How Ceramic Tiles Are Made: Report from the Kerama Marazzi Factory in Orle

Kerama Marazzi has two factories. One is located in Stupino, outside Moscow, where most of the ceramic granite is produced. The other, by the way, is one of the largest in the world – in the city of Orle: here they manufacture ceramic tiles, ceramic granite, mosaics and decorative items.

The factory in Orle is so large that it takes at least 5 hours to get acquainted with the production process. We only had two, so we focused on the most important details.

About Kerama Marazzi's Products

There are several types of production at the Kerama Marazzi factory in Orle. The most voluminous is BICO (short for bicutture, from Italian – "double firing"). This is where wall ceramic tiles are produced. The volume of products manufactured at this production line is impressive: 1.3 million square meters per month! For comparison: that's about 182 football fields.

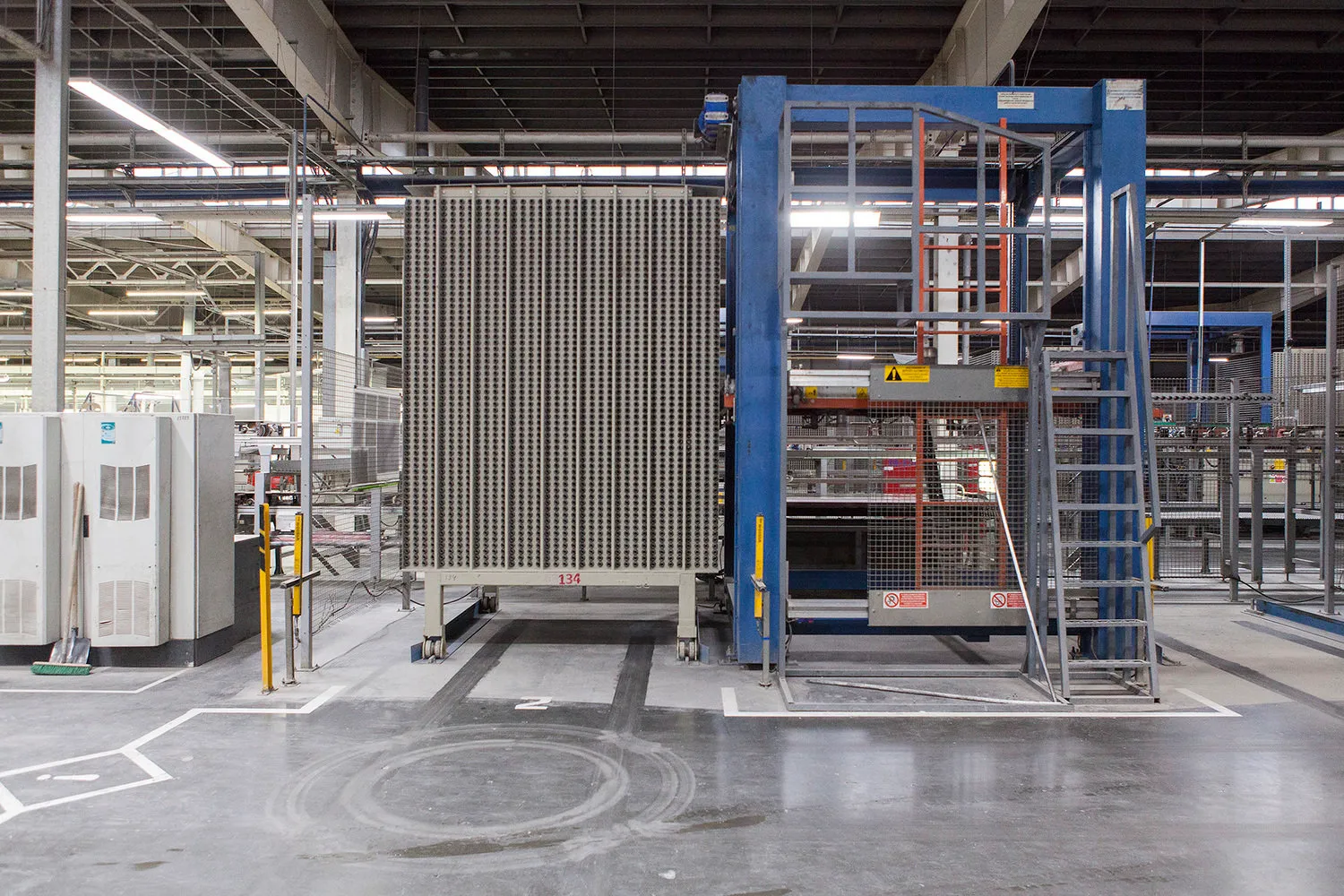

BICO 5-6 Production, Kerama Marazzi Factory in Orle.

BICO 5-6 Production, Kerama Marazzi Factory in Orle.The second most significant production line at Kerama Marazzi is MONO (from monoculture, from Italian – "single firing"). This is where floor ceramic tiles are made. The volume of products exceeds all limits: over 1 million square meters of various formats and textures per month!

At the GRES production line, ceramic granite is manufactured – 500 thousand square meters per month! Ceramic granite is a universal type of tile. It is characterized by resistance to mechanical damage, minimal water absorption, and as a result, easily withstands temperature fluctuations (the surface can even be used for external finishing).

The factory produces ceramic granite imitating various materials: for example, wood, stone, concrete.

Storage Area of Fired Tiles. Kerama Marazzi Factory in Orle.

Storage Area of Fired Tiles. Kerama Marazzi Factory in Orle.There is a separate story – the third firing production: special, decorative items and mosaics. At this section, product accounting is done piece by piece, and over 1 million items are manufactured per month! An incredible amount.

Large batches of ceramic products are produced on automated production lines, while exclusive decorative elements are made in small batches by hand. Interestingly, to add decoration to tiles, precious metals like gold and platinum are sometimes used.

Cut Mosaic, Kerama Marazzi.

Cut Mosaic, Kerama Marazzi.How is wall ceramic tile made?

We managed to follow the entire process from start to finish. With a camera in hand.

Stage 1: Raw Material Selection According to Kerama Marazzi's Technical Specifications

All natural materials needed to make ceramic tiles are delivered to the clay storage area, where they are also stored. The main ingredients of the pressing powder: clay (taken from a quarry in Maloarkhangelsk), feldspar, sand, limestone and chamotte – recycled waste.

"Ceramics make ceramics," employees of the factory respond with a smile to the question of why chamotte is needed in the mixture. – And our company also strives for zero-waste production, and using waste products is an important part of this process".

Clay Storage at the Kerama Marazzi Factory in Orle.

Clay Storage at the Kerama Marazzi Factory in Orle.All ingredients of the pressing powder are weighed on special industrial scales, and then in the required quantities (the numbers are kept secret and determined according to the production technical specifications) they are sent via conveyor belts to another workshop where they enter large grinders.

Front loader loading clay on industrial scales at the Kerama Marazzi Factory.

Front loader loading clay on industrial scales at the Kerama Marazzi Factory.Stage 2: Production of Pressing Powder

In the grinders, in addition to clay, feldspar, sand, limestone and chamotte, water and gravel are also added. The latter is mined in the English Channel. This gravel has an optimal chemical composition and shape and is an indispensable ingredient for producing pressing powder.

All ingredients are ground in the grinder – a large rotating metal cylinder – into a liquid mass or slurry.

All ingredients loaded into the large grinder. Production of slurry begins.

All ingredients loaded into the large grinder. Production of slurry begins.The slurry flows into a huge underground storage tank where the liquid mixture is kept in a uniform state using constantly rotating blades.

From the storage tank, the slurry is pumped into an atomizer. The side walls of this device are equipped with nozzles for supplying hot air. Under the effect of the latter, the slurry turns into granulated pressing powder.

Production of Pressing Powder. The Atomizer is in the Center of Attention.

Production of Pressing Powder. The Atomizer is in the Center of Attention.But the process of its production does not end here. The pressing powder is sent via conveyor belts to silos – storage and maturation areas. Only after a day, when the pressing powder becomes a uniform mass, is it sent to the presses. And then creativity begins.

Granulated Pressing Powder Moving on Conveyor Belts to Silos.

Granulated Pressing Powder Moving on Conveyor Belts to Silos.Stage 3: Production of Green Tiles on Presses

It is here, on the press area, that green tiles (unfired tiles) are made, which already have their shape and structure. Whether they will be large or small format, smooth or textured, depends on the selected counter mold and punch – important elements of the press.

All tiles are made with the mounting side up, flipped on the conveyor belt and sent to the next production area of BICO, where they await their first firing.

Stage 4: Kiln

There is a lot of moisture in the green tiles, so they are very fragile and can easily be broken. To make them more durable, the first firing is required. Before entering the kiln, the green tile's mounting side is covered with engobe – a special composition, as experts explain, "to prevent burning".

The length of the first firing kiln is 119 meters. The firing cycle lasts 34 minutes. During this time, the tiles are baked and slightly shrink – on average, about 2 mm is lost from each side. After the first firing, the product is called a biscuit, which is much stronger than the green tile and has its final shape.

Length of First Firing Kilns – 119 Meters.

Length of First Firing Kilns – 119 Meters.All biscuits are automatically loaded onto a cart – storage area for tiles that just came out of the kiln. One cart has 60 "floors", on which 216 square meters of 20x40 cm format tiles are placed.

As soon as the cart is loaded, the TJV system (automatic product handling system) moves it to the temporary storage area. Here, under the influence of the correct temperature, the tiles cool down (takes about 2 hours), and then they are sent to the glazing area.

Biscuits (Single-fired Tiles) Loaded onto a Cart.

Biscuits (Single-fired Tiles) Loaded onto a Cart.Stage 5: Glazing

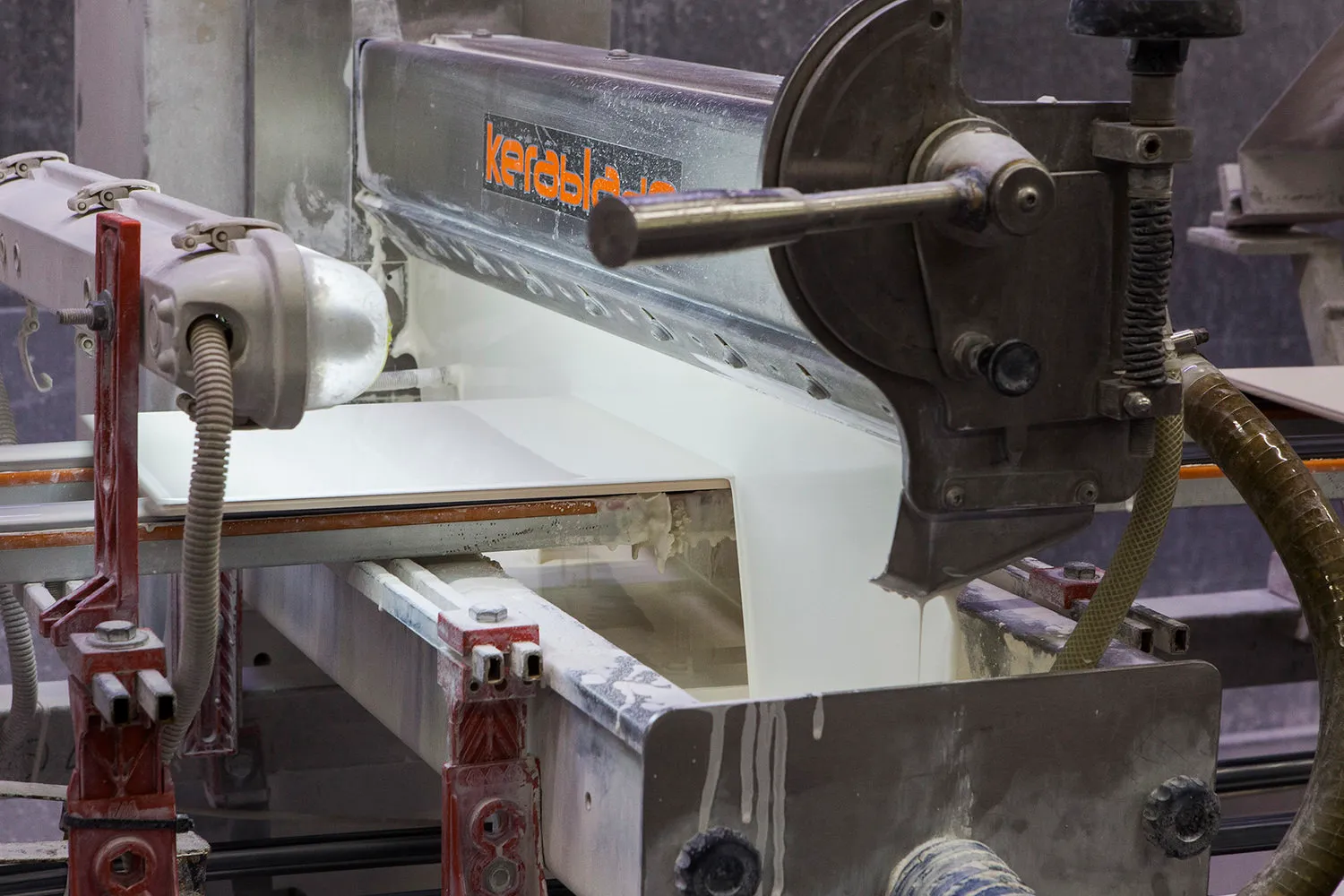

The operation of the glazing line is carefully monitored by an operator. Before the biscuit is coated with glaze, each edge of the tile is cleaned (to make sure they aren't sharp), dust is shaken off with a brush, and the pre-moistened biscuit is covered with engobe – it hides surface roughness and makes the surface white. This creates the perfect base for subsequent decoration.

Next, the biscuit is coated with glaze, which contains frit (molten glass). It's time to apply the pattern.

Glazing Line at the Kerama Marazzi Factory in Orle.

Glazing Line at the Kerama Marazzi Factory in Orle.Stage 6: Applying Patterns to Ceramic Tiles

Several variants of pattern application are used in production. Traditional methods include silk screening and rotative printing. The new trend is digital printing, which allows reproducing any pattern on the tile surface with photographic accuracy.

Digital Printing – a New Milestone in Pattern Application on Tiles.

Digital Printing – a New Milestone in Pattern Application on Tiles. All Equipment at the Kerama Marazzi Factory – Italian.

All Equipment at the Kerama Marazzi Factory – Italian.There are 30 digital machines in use at the two Kerama Marazzi factories. This is more than all other domestic manufacturers combined. New technologies allow the factory to work ahead of time and delight its customers with high-quality tile patterns and a wide range of products.

Stage 7: Second Firing

The factory says that the second kiln firing cycle forms the plant's productivity. The process takes from 34 to 57 minutes (depending on tile format). After the second firing, you get finished products that are sent to the sorting line.

After the Second Firing, Tiles Are Called 'Glazed'.

After the Second Firing, Tiles Are Called 'Glazed'.Stage 8: Sorting

The sorting line thoroughly scans all products for defects. Defective items are removed from the line, and quality products are packed into boxes. Each box is automatically labeled with the tile's article number, tone and grade. Finished products are stacked on pallets by robots and... wait for shipment!

Sorting Line. Wall Ceramic Tiles Ready for Sale.

Sorting Line. Wall Ceramic Tiles Ready for Sale.+ 10 Interesting Facts About the Kerama Marazzi Factory

Fact 1. The History of Kerama Marazzi Began with the Factory in Orle

In 1988, an Italian manufacturer of ceramic industry equipment – the company WELKO Industriale S.p.A. – became a founder of the "Velor" factory in Orle. In winter 1992, the first batch of ceramic tiles – "February Snow" – came off the new factory's conveyor.

Fact 2. Kerama Marazzi Is a Full-Cycle Production

The company owns and carefully controls the entire production chain, from ingredient extraction in quarries to retail trade.

Fact 3. The Glaze Made at the Factory in Orle Is of Very High Quality

Italian experts rated the Russian glaze from Kerama Marazzi as one of the best in the international market.

Frit Production at the Kerama Marazzi Factory in Orle.

Frit Production at the Kerama Marazzi Factory in Orle. Glass Melting Furnace at the Kerama Marazzi Factory in Orle.

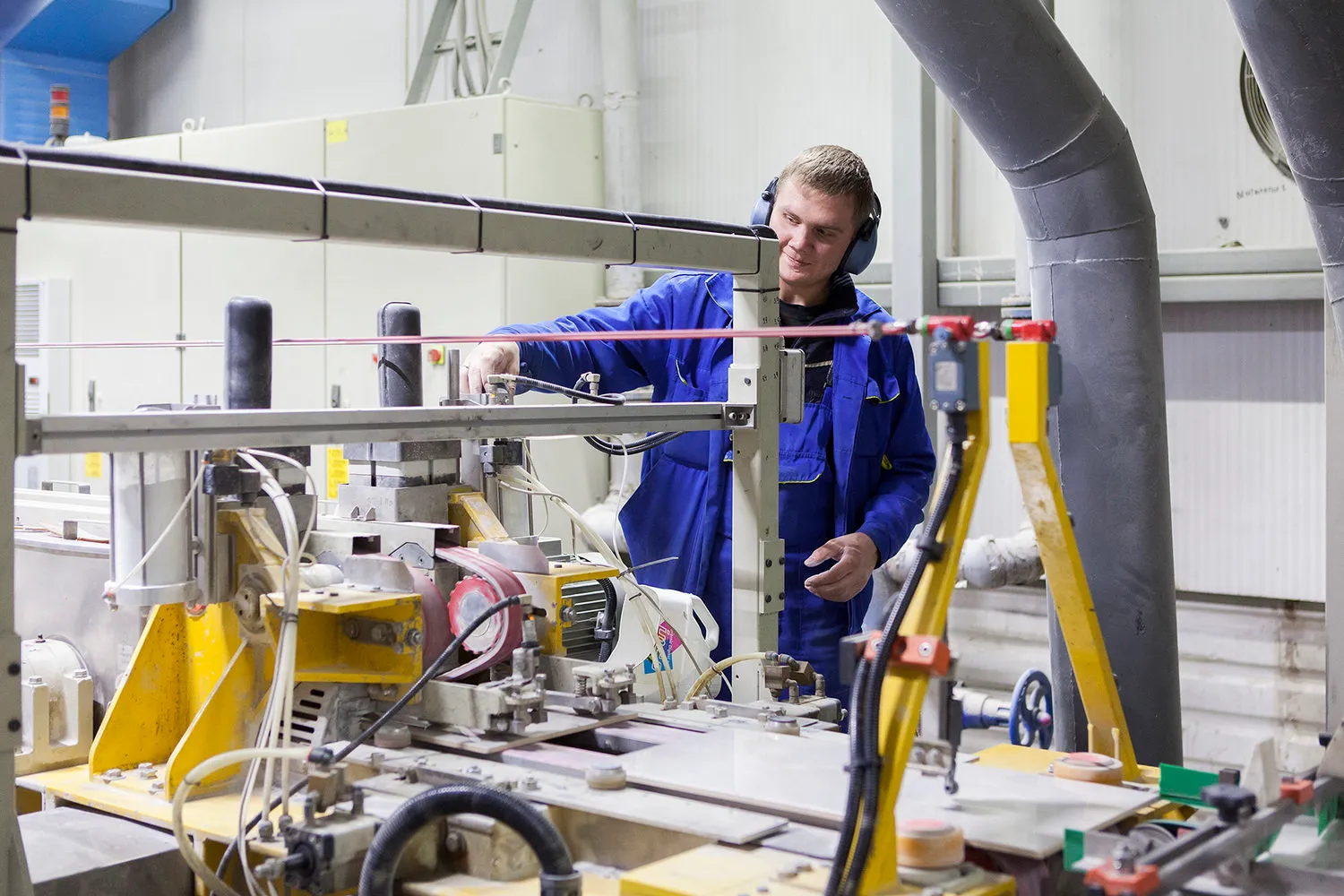

Glass Melting Furnace at the Kerama Marazzi Factory in Orle.Fact 4. All Equipment Is Italian

The factory is highly advanced and operates 24 hours a day, 7 days a week. All processes are mechanized. People are only needed for control and setting up the newest imported equipment.

Ceramic Tile Production at the Kerama Marazzi Factory in Orle.

Ceramic Tile Production at the Kerama Marazzi Factory in Orle. Ceramic Rollers for the Furnace Are Imported from Italy.

Ceramic Rollers for the Furnace Are Imported from Italy.Fact 5. Kerama Marazzi's Product Range Is Constantly Expanding

For example, in spring 2016, the production of small-format tiles began at the factory in Orle – one of the most popular materials for interior finishing and decoration.

Third Firing Production at the Kerama Marazzi Factory in Orle.

Third Firing Production at the Kerama Marazzi Factory in Orle.Fact 6. Continuous Quality Control

The factory pays close attention to the standards of ceramic tile production. Operators make hourly samples. All defective products are sent for reprocessing, turning into chamotte and sent back to production to make pressing powder.

Fact 7. Variety of Formats and Decorations

Kerama Marazzi offers comprehensive design solutions: walls, floors, decoration – the factory produces all decorative ceramic elements. Kerama Marazzi also releases new thematic collections every year, including tiles in new formats.

Quality Control at the Kerama Marazzi Factory.

Quality Control at the Kerama Marazzi Factory.Fact 8. Working with Professionals

The company involves both Russian and foreign designers and artists in tile design development. For example, the "Neapolitan Collection" was created in collaboration with Mr. Franco Calise, an Italian ceramic artist.

Fact 9. Staff Motivation System

The Kerama Marazzi factory has implemented several systems to improve production. The main one here is the "Kaizen" system. This means that every employee can propose an idea to management for optimizing labor and, if approved, receive monetary compensation.

Fact 10. Kerama Marazzi Tiles Are Loved Beyond Russia's Borders

This is not surprising. They are also sold in Scandinavian countries, Germany, England and the USA.

Ceramic Tile Production at the Kerama Marazzi Factory in Orle.

Ceramic Tile Production at the Kerama Marazzi Factory in Orle.Photo: Yuri Grishko

Need a renovation specialist?

Find verified professionals for any repair or construction job. Post your request and get offers from local experts.

You may also like

More articles:

Guide: 5 "Our" Scandinavian Interiors

Guide: 5 "Our" Scandinavian Interiors How to Choose and Place a Mirror: 7 Feng Shui Tips

How to Choose and Place a Mirror: 7 Feng Shui Tips 13 Tips from Jean-Louis Deniot for Young Designers

13 Tips from Jean-Louis Deniot for Young Designers 12 Interesting Facts About New Year

12 Interesting Facts About New Year 11 Green Antidepressants for City Residents

11 Green Antidepressants for City Residents How to Choose Material for House Facade Cladding

How to Choose Material for House Facade Cladding 5 Best Layout Options for Bathroom in Standard Panel House

5 Best Layout Options for Bathroom in Standard Panel House 10 Things to Get Rid of Right Now

10 Things to Get Rid of Right Now