Production Campus Designed with an Eco-Friendly Approach

Project: Organic Products Production Campus HEG GIDA

Architects: IGLO Architects

Location: Balikesir, Turkey

Area: 1,399,308 sq ft

Year: 2022

Photos: Fethi Izad

The HEG GIDA Organic Products Production Campus was designed by IGLO Architects with an eco-friendly approach to processing, sustainable development and carbon emission minimization without any vulnerabilities in the hygiene chain.

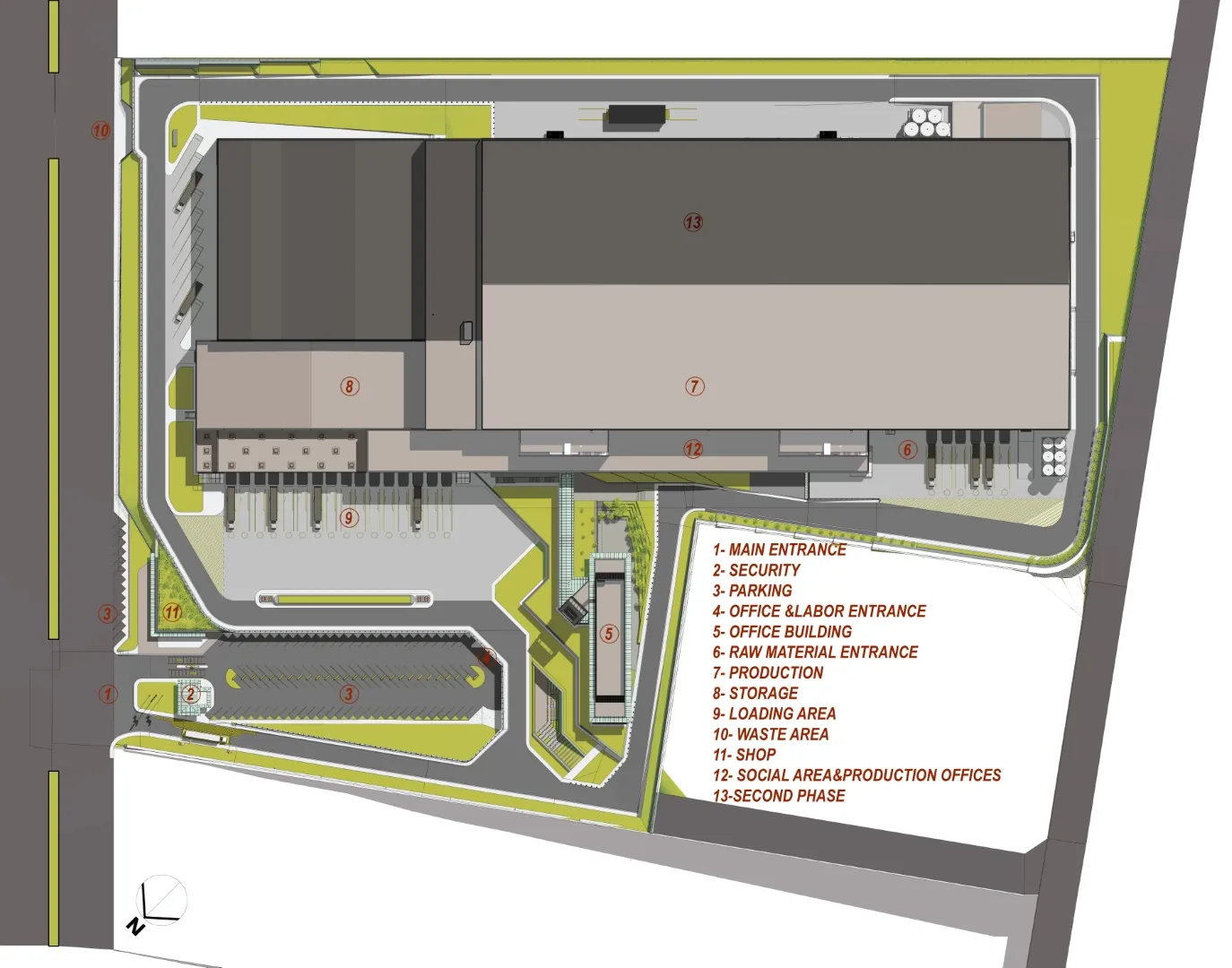

The HEG GIDA Organic Products Production Campus, whose design process was executed by co-owners IGLO Architects, Architect Essen Akyar Karoglu, and Zafer Karoglu, is a production and management facility with a covered area of 130,000 sq m built on an 85,000 sq m site. The height difference between the two roads adjacent to the site is 36 meters, enabling floor levels with entrances at their level. The spacious maneuvering zone includes administrative, production and logistics departments located on elevated areas, with the entrance platform equipped with technical structures, a shop, and main entry.

As food safety is a priority in the HEG GIDA Organic Products Production Campus, guests first enter a designated area bounded by natural boundaries of the square designed as parking, then proceed to the reception zone for using various elevators and stairs reserved for guests, staff, and office employees. The reception area was designed with a café concept, enhancing its informational function for providing daily fresh baked goods to guests and hosting meetings in conference rooms. Connected to the production block by a bridge, the clock tower serves as the building's distribution shaft and is used for directing staff.

People can only enter the building after passing through a changing room where they put on sterile and hygienic clothing to ensure no vulnerabilities in the hygiene chain. After entering this part of the building, where offices, dining areas, and social spaces are used, they must go through the same sterilization and changing process to enter production zones on respective floors. Ceiling, floor, and wall connections are made from high-fire-resistant materials suitable for washing and excluding dust, dirt, and bacteria. Intermediate floors were built on production floors to house all electrical, mechanical, and technological lines to create hygienic spaces, thereby ensuring the absence of elements such as cables and drainage pipes that accumulate pollutants in main halls. Ventilation ducts passing through the hall are made from special washable textile materials.

Except for the oven section on the top floor, all production zones are designed as large refrigerators with air conditioning systems set at +4°C, -15°C, -25°C, and -45°C. Products produced on the floors are prepared for dispatch after entering storage systems with 4.0 technology through conveyors.

The administrative building is designed to offer a view of the wide plain of Balikesir, campus entry, and shipment zones while ensuring direct communication between each office unit and the gardens on the floors.

Sustainable development was one of the most important factors in planning. The entire workflow was planned using energy and waste-saving solutions. Organic wastes generated during the process were composted. Energy and heat produced by cooling and heating systems were reused with almost zero losses.

The project includes a technical floor oriented toward research and development in collaboration with universities to develop mechanical and technological tools that improve agricultural productivity used as raw materials. The project aims at implementing these developed tools in contract fields to ensure organic safety, agricultural efficiency, and product quality.

Various colors, materials and textures were used on the building facades shaped by principles of process, workflow, and height differences in the land area including administrative structures, controlled squares, and social zones positioned considering their dominance over the territory. Green zones created in areas where plants were only allowed under strict control for food safety purposes provided a softer atmosphere within the industrial environment.

It was important to build a campus that functions according to the company's vision following an eco-friendly production approach. Therefore, the structure was built in accordance with requirements for obtaining a German Green Building certificate (DGNB).

The goal was to create a business model applying an eco-friendly approach to processing and sustainable development, focusing on carbon emission minimization, becoming a model in Turkey and around the world.

Despite this being a large building with nearly twice the covered area compared to its site, the architectural design process followed principles of creating a building with large open spaces that are not overly bulky from a human perspective and harmonious with the environment. The project was carefully designed to ensure effective use of natural light, including balconies, terraces and gardens for fresh air access. Technically supported zones required for mechanical and electrical infrastructure and generator needs were placed beneath the maneuvering zone to allow direct intervention on the same floor. Located between the shop and reception area with a linear facade grid, these zones form the structure of the lower square.

Waste rooms with garbage containers allowing the facility to reach waste collection services without entering the building were made available via waste chutes and tunnels to prevent insect contamination and pollution in the area.

The roofs of production buildings were designed to accommodate photovoltaic panels for electricity generation. Since the organized industrial area where the building is located invests in wind energy, clean energy was purchased from them to meet electrical supply system needs.

Preferred systems in the process were those operating with environmentally clean carbon dioxide and ammonia gases. Oil separators were used to prevent environmental contamination. Natural gas usage for heating drinking water and technological water was reduced by 80% through combining heat from steam ovens and hot oil boilers.

All buildings were equipped with high-insulation materials, each specially painted with environmentally clean paints produced by natural methods.

-Project description and images provided by pRchitect

Need a renovation specialist?

Find verified professionals for any repair or construction job. Post your request and get offers from local experts.

You may also like

More articles:

Festive Christmas Calendar for Interior Inspiration

Festive Christmas Calendar for Interior Inspiration Historic Long Building, Combining Past and Future

Historic Long Building, Combining Past and Future Nature-Inspired Design: The SGA Residential House by REDA

Nature-Inspired Design: The SGA Residential House by REDA Designer Cot for Modern Interior

Designer Cot for Modern Interior Immersion in Hughes Marino's Favorite Office Spaces

Immersion in Hughes Marino's Favorite Office Spaces DIY Home Decoration with Paint by Numbers and Diamond Painting

DIY Home Decoration with Paint by Numbers and Diamond Painting Dreamy Wooden-Glass Cabin for Open Space

Dreamy Wooden-Glass Cabin for Open Space Duplex as a Family Home in Paris

Duplex as a Family Home in Paris