There can be your advertisement

300x150

Insulation of Attic Rooms

The term 'attic' entered common usage in Europe after 1630. This happened when architect François Mansart began using attic space under a sloping roof for residential and utility purposes. Before modern building technologies and materials, such spaces were used only by the poorest populations, forced to endure extreme summer heat and winter cold.

When planning to build an attic floor, it's best to choose lightweight materials. This helps minimize structural weight, reducing load on lower building elements. Therefore, using thin-walled cold-formed steel profiles, glued timber, or solid wood with antiseptic treatment is both practical and effective.

Beyond structural weight, maintaining comfortable indoor temperatures is critical—especially in Russia’s harsh climate, which makes insulation more challenging than in many European countries.

Heat Under the Roof

Attic heat loss exceeds that of lower floors due to greater surface area exposed to outdoor conditions. The key to effective attic insulation is creating a continuous insulation layer around the entire perimeter, along with proper ventilation, vapor barrier, and waterproofing around the insulation layer.

This is difficult to achieve, as indoor air temperature near the ceiling can exceed floor-level air temperature by more than 2°C, increasing heat loss. Additionally, warm air holds more moisture than cold air—this leads to condensation buildup under the roof.

Choosing the Right Insulation

Since attics are typically intended as living spaces, insulation selection must consider not only thermal conductivity and density, but also fire safety. Most experts recommend rock wool boards with a density of about 40 kg/m³. This material is non-combustible, resistant to deformation, breathable, and has low moisture absorption.

For Russia’s middle climate zone, use rock wool boards 200–250 mm thick. In southern regions, use 160–180 mm thick boards. Polystyrene boards are not recommended due to fire hazards and low vapor permeability. Glass wool mats are less durable due to shape degradation over time.

Insulating Roof Slopes

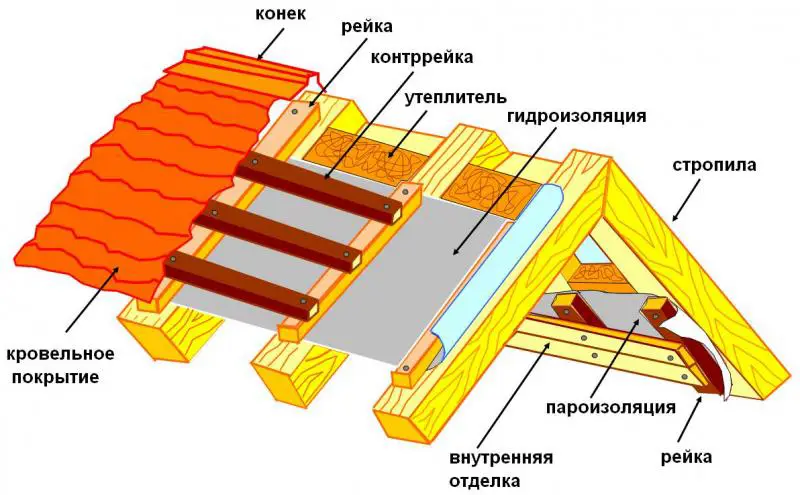

Roof slope insulation uses rock wool boards placed between rafters. When rafters are too thin, treated wooden battens are attached. Insulation is then installed in two layers: one between rafters, the second between battens. For maximum efficiency, arrange layers so one covers the joints of the other.

To remove moisture that may enter under the roof, create an air gap of 25 mm between roof and insulation for metal roofing, tiles, or galvanized steel sheets. Use a 50 mm gap for roll roofing, flexible bitumen tiles, galvanized steel, or asbestos-cement sheets.

Vapor Barrier Installation

To prevent moisture from indoor spaces from penetrating the roof cavity, install vapor barrier material. Apply with a 150–200 mm overlap and secure to rafters using wooden furring strips. If using insulation with a foil backing, install it so the foil faces inward.

Insulating Walls

Heat loss occurs not only through the roof but also through attic walls. Insulation can be applied externally or via internal framing. A continuous vapor barrier between walls and roof slopes is essential. Use overlapping joints at all connections.

Additional Insulation

If existing insulation is insufficient, consider adding a new layer on top. The downside is the need to remove the roof sheathing, cladding, and install a new support frame—though this preserves internal space.

An alternative method involves building a new wooden frame between which insulation is placed. Then apply vapor barrier and finish with plywood, gypsum board, or wooden cladding. The advantage is no need to dismantle the roof; the downside is reduced usable area.

Proper attic insulation ensures a comfortable indoor climate and reduces overall heating costs—since insulating the attic reduces the building’s total heat loss.