Roofing with Profiled Sheet

Throughout history, people have strived for comfortable homes and reliable roofing. Steel is ideal for these purposes, but its weight limited its use in roofing. This problem was solved by corrugation, producing thinner, lighter steel sheets with a trapezoidal profile that ensures strength and rigidity.

These corrugated steel sheets are known as profiled sheets.

Key Features of Profiled Sheets

Profiled sheets are used in construction for:

- roofing buildings and structures;

- cladding walls;

- building fences and partitions;

- forming formwork for concrete blocks.

Depending on application, profiled sheets are marked as C, N, and NS.

- C – galvanized profiled sheet, used for fences, walls, and façade cladding. Not suitable for roofing due to low wave height, which may allow water penetration.

- N – roofing profiled sheet. Features a high wave and capillary groove for water runoff, making it ideal for roofing. It has a smaller useful width than wall sheets but greater strength and load capacity, allowing use not only in roofing but also in floor slabs.

- NS – universal profiled sheet, suitable for both roofing and walls.

Profiled Sheet Marking

Marking varies by sheet width and wave height. For example, N44-1000-0.7. Let's break it down:

- N – intended for roofing,

- 44 – wave height (in mm),

- 1000 – installation (useful) width (in mm),

- 0.7 – sheet thickness (in mm).

Roofing sheets like N44-1000 are used in large industrial projects and can withstand snow loads and strong wind gusts due to their high corrugation and wide installation width.

Advantages of Roofing Profiled Sheets

Compared to metal roofing tiles, profiled sheets offer several benefits. For example, metal tiles require a minimum roof slope of 14°, while profiled sheets can cover even flat surfaces. Key advantages include:

- Long lifespan (up to 50 years);

- Cost-effectiveness (the most affordable roofing material);

- Simple installation (can be done year-round);

- Resistance to physical and weather conditions;

- Wide range of colors, shapes, and sizes.

Protection from Moisture

Profiled sheets must reliably protect homes from rain and external moisture. Correct roof pitch calculation is essential—otherwise, rain or wind may penetrate under the roof covering.

Special attention must be given to vapor and waterproofing. Poor waterproofing may allow water to enter the roof structure, causing wetting of rafters and sheathing, mold formation, and damage to interior finishes.

To prevent moisture ingress, under-roof waterproofing membranes and ventilation gaps are used. Ventilation prevents the sheet from overheating from the inside.

Installation of Roofing with Profiled Sheets

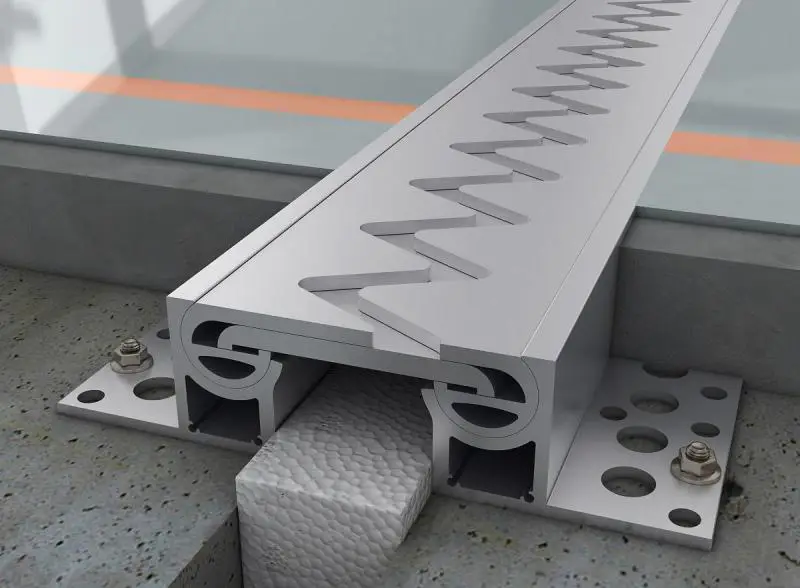

Roofing with profiled sheets involves several steps. The base is wooden battens or steel purlins (if corrugation height is 40 mm or more).

First, profiled sheets must be cut. Markings are made on each sheet, and cuts are made manually. Use a special tool—drill attachment like shears—for clean edges and full-direction cutting. Manual metal tools like saws or snips can also be used.

Before installing sheets on rafters, insulating materials are laid, secured with struts, and then horizontal battens are installed. Accurate batten spacing is critical, as fasteners will attach to them.

The main rule for proper installation: avoid damaging the coating. If scratches appear, they must be painted with special coating. All cut edges must be treated with the same paint. After installation, remove all metal shavings and debris from the roof.

Need a renovation specialist?

Find verified professionals for any repair or construction job. Post your request and get offers from local experts.