Ecopan Technology

In recent years, frame house construction technology, also known as Ecopan technology, has taken a leading position in individual housing. This is understandable, as it enables the construction of strong, reliable, and well-insulated (if technical parameters are followed) buildings in a remarkably short time. Although brick houses offer greater strength, energy-efficient insulated panels can withstand vertical loads of up to 28 tons.

This is not the limit, as additional reinforcement with connecting beams is possible!

The Warmest Walls

Thermal capacity and energy efficiency of walls made from sandwich panels have no competitors in the construction materials market. This is easily explained by the fact that they consist of insulating material (mineral wool, polyurethane foam, or polystyrene) for up to 80%. As a result, residents of such cottages save significantly on heating and air conditioning. Regarding durability, the first examples have already lasted up to 70 years, and the frame house construction technology continues to evolve and improve.

How the Panel Is Constructed

Modern SIP panels consist of two thin OSB boards, with insulation material filling the space between them. Under pressure during gluing, the polystyrene layer causes both boards to work under load together, making the insulation itself a load-bearing component and playing a key role in the overall strength of the element.

OSB boards were invented in the USA in the 1980s and are made from specially shaped wood chips bonded with water-resistant resin under high pressure and temperature. Numerous attempts have been made to replace OSB with cement-chip, fibrolith, or glass-magnesium panels, but due to various reasons (brittleness, low frost resistance, high cost), no viable alternative has been found yet.

What Is a House Kit?

A major advantage of frame-panel house construction is the ability to implement complex architectural designs. If you purchase a ready-made house kit, which most customers prefer today, you can be confident in excellent final quality, regardless of the builder’s skill level.

The house kit includes sandwich panels pre-cut in industrial conditions according to a specific project, fasteners, connecting and structural elements. Assembling the finished house resembles a LEGO constructor. All parts require no fitting. Moreover, the panels will even feature special tongues for assembly using a tongue-and-groove system.

If you purchase a complete kit, it will include not only wall panels but also roof truss structures and even installation foam. All structural characteristics of the material are calculated and accounted for during the design phase. While it's possible to try assembling individual components yourself, this may compromise the overall structural integrity and performance.

Many are attracted to this technology because of the wide range of cladding materials available (facade panels, modern vinyl siding, wooden block house, etc.), allowing standard homes to gain individuality and a unique appearance.

How Much Does It Cost to Build a House?

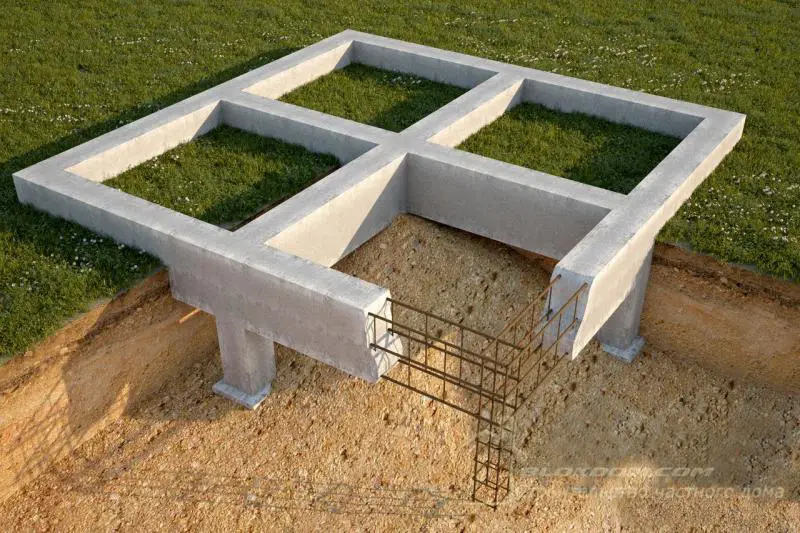

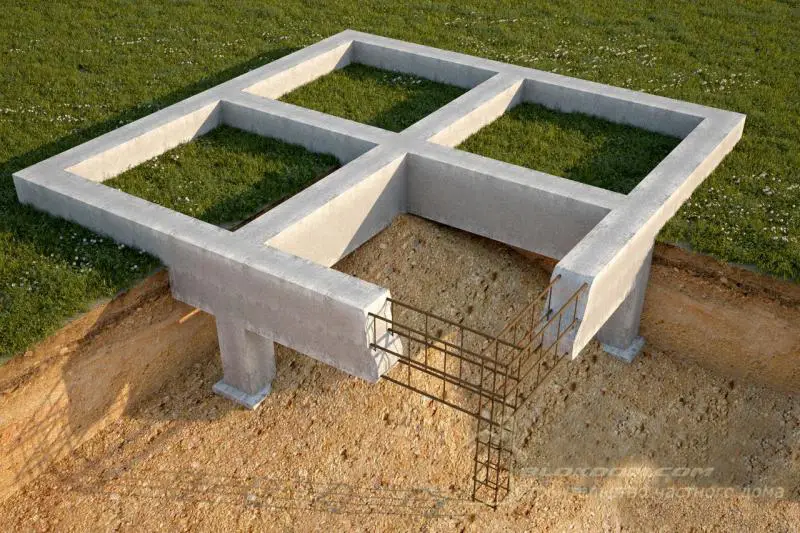

Another important factor is the relatively low cost of such housing. Low material costs are combined with significant savings on foundation work (as foundations need to be much less massive than those for brick houses). Low labor costs and uniquely short construction timelines (an experienced team of installers can assemble a house kit in one week) provide additional benefits.

The Bitter Drop

Like any technology, frame-panel house construction has drawbacks. The primary concern is relatively low fire safety. Therefore, material selection for finishes must consider this factor.

During installation, it’s advisable to avoid prolonged exposure of panels to moisture, as they may warp. After final finishing, they will be adequately protected against moisture.

Keep in mind that the relatively thin wall thickness imposes certain limitations on the weight of furniture and household items hung on them.

Frame-panel construction is known by various names, including Canadian technology, Ecopan technology, and SIP (Structural Insulated Panel) technology. Other terms are also used, including 'green home,' as this technology is considered one of the most environmentally friendly.

Need a renovation specialist?

Find verified professionals for any repair or construction job. Post your request and get offers from local experts.