Strip Foundation

Strip foundations come in several types and are highly versatile for any type of construction. By definition, they are structures that transfer and distribute loads to the ground. These foundations are laid under all walls of a building and have a uniform cross-section at every point.

They are used from fence construction to 2- to 3-story brick houses.

Depth and Width of Strip Foundation

Foundation cross-section is calculated based on several factors, such as:

- depth of soil freezing,

- type of foundation soil and presence of groundwater,

- building load on foundation and wall thickness.

According to national standards, foundation depth is determined as soil freezing depth + 20 cm. This value ranges from 50 cm to over 2 m depending on the region in Russia. Strict adherence to these rules is essential when constructing large residential structures.

For lightweight structures, outbuildings, fences, and similar constructions, you may deviate from these standards and set foundation depth at 20–50 cm below ground level. The top surface of the foundation should be at least 20 cm above ground level, considering site leveling and grading.

Foundation base width is determined by wall thickness and total structure weight. In most cases, foundation thickness should match wall thickness.

In some cases, it must be slightly wider. For example, when the total structure weight is high but wall thickness is low. In such cases, foundation thickness is determined by calculations, but usually adding 10–20 cm is sufficient.

Reinforcement of Strip Foundation

To increase load-bearing capacity (ability to withstand specific loads), strip foundations are reinforced. Reinforcement involves binding the entire foundation perimeter with rebar.

Depending on load, one or two layers of reinforcement are used. In single-layer reinforcement, rebar is placed at the top or bottom of the foundation; in double-layer reinforcement, it is placed at both top and bottom. Reinforcement layers consist of 1, 2, 3, or more wire runs. For enhanced strength, transverse and complex reinforcement methods are used.

Reinforcement layers are tied horizontally in transverse reinforcement and vertically in complex reinforcement. Rebar thickness is also calculated based on required load-bearing capacity.

Monolithic Strip Foundation

The strongest and most reliable type among strip foundations is the monolithic strip foundation. Monolithic foundations are those installed directly on-site during construction.

These foundations are made using only concrete (monolithic); concrete and rubble stone (concrete-rubble); where concrete exceeds rubble; or concrete and rubble, where rubble exceeds concrete (rubble foundation). In the first two cases, reinforcement is possible; in the last, reinforcement is not feasible, as rubble foundations are built using masonry techniques with special stones.

Prefabricated Strip Foundation

A strip foundation assembled from factory-made reinforced concrete elements transported to site is called a prefabricated strip foundation. This method requires specialized equipment. All components are heavy and cannot be installed manually.

The entire structure consists of elements labeled FL (pads) and FBS (blocks), with varying widths and lengths, depending on structural requirements. Unlike other strip foundations, this method eliminates the need for full perimeter formwork. Formwork is used only at joints between elements. Wall construction can begin within a few days after installation.

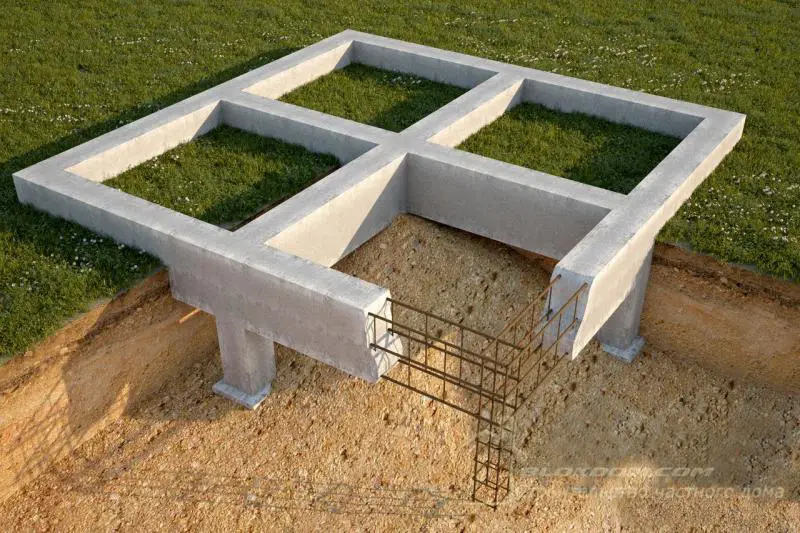

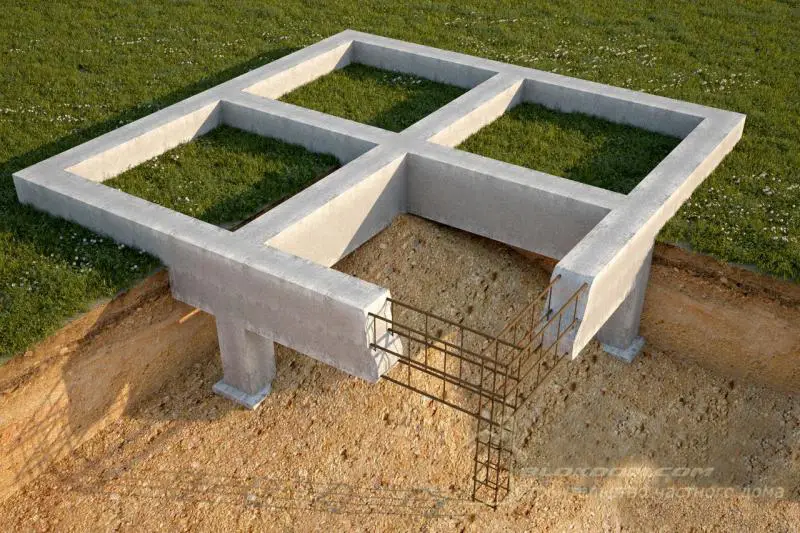

Combined Pile-Strip Foundation

In some cases, strip foundations are combined with piles. Pile installation techniques vary, but in private construction, only cast-in-place reinforced concrete piles are used.

After trench preparation, layout is marked and holes (pockets) are drilled. These holes are then reinforced and filled with concrete. Rebar extending from the holes is connected to the main reinforcement framework of the foundation.

Pockets should be placed no more than 2 meters apart, avoiding door and window openings. They must also be placed at each corner of the foundation.

Building a Strip Foundation Yourself

When building a foundation yourself, using a monolithic or concrete-rubble strip foundation is most practical. All work can be done independently without specialized equipment or tools. The process is as follows.

Site layout and axis marking. First, determine the future building’s position on the plot. Choose a point on the site as one corner of the building and mark all external corners by stretching string or twine to indicate the outer edge of the foundation. After outlining the perimeter, stretch a second string parallel to the first, at a distance equal to the foundation’s thickness. Also mark load-bearing walls and partitions.

Next, dig the trench. If trenches are dug carefully, maintaining vertical walls without collapse or defects, underground formwork may be avoided. Begin digging from the lowest point of the foundation, ensuring horizontal alignment.

The base plane must be perfectly horizontal, as optimal load transfer occurs when the load direction is perpendicular to the load-bearing surface. Dig the trench to a predetermined depth. If the soil at the required depth does not meet prior assumptions, dig deeper.

A sand cushion is laid on the leveled trench bottom. A 20–50 mm layer is sufficient, as thicker layers increase the risk of uneven settlement. Concrete can be poured directly onto the sand, but other options exist. For example, a layer of crushed stone is placed on the sand and leveled with a cement-sand mix.

After the mix dries, install the rebar framework. Lay the bottom layer of rebar and tie it with transverse bars. Do not weld rebar joints—use wire ties instead. Welding reduces flexibility and tensile strength, negatively affecting performance. Also, welded joints are more prone to corrosion.

Then install the formwork. Use any flat materials: timber, plywood, MDF, or sheet asbestos cement. Formwork panels must be installed vertically, at the boundary between concrete and soil. Secure them by driving stakes and using ground supports. The top edge of the panel should be slightly above the designed foundation height or exactly level, though the latter is difficult to achieve.

After securing panels on both sides of the foundation, install cross-braces every 80–100 cm to prevent formwork bulging. Then install the upper part of the reinforced framework and proceed to pouring.

Do not remove formwork immediately after pouring. Concrete gains strength slowly and needs protection from direct sunlight, regular moisture, and heating in cold weather.

Need a renovation specialist?

Find verified professionals for any repair or construction job. Post your request and get offers from local experts.