Foundation on Screw Piles

In rural construction, sites are often encountered where the soil does not allow traditional foundation laying methods. In such cases, a screw pile foundation will come to the rescue, effectively performing its function on any soil type, including sandy, clayey, and peat soils. Features of the design and its advantages. Like many other technologies, the construction of a screw pile foundation was first introduced by military builders.

In rural construction, sites are often encountered where the soil does not allow traditional foundation laying methods. In such cases, a screw pile foundation will come to the rescue, effectively performing its function on any soil type, including sandy, clayey, and peat soils.

Features of the Design and Its Advantages

Like many other technologies, the construction of a screw pile foundation was first introduced by military builders. Today, buildings are constructed on this basis in areas with unsuitable soil for traditional structures, or where it's necessary to preserve the surrounding landscape. Installing screw piles does not require digging large excavations or using heavy machinery, which positively affects the environment and speeds up work.

Foundation construction using screw piles can be carried out year-round; it remains strong and durable regardless. The cost of this structure is at least 40% lower than traditional strip foundations, allowing for significant savings. Additionally, when dismantling a temporary structure, the piles can be removed and reused, substantially reducing the cost of a new building. Moreover, this foundation type allows for additions to a building without causing settlement or damage to the main structure.

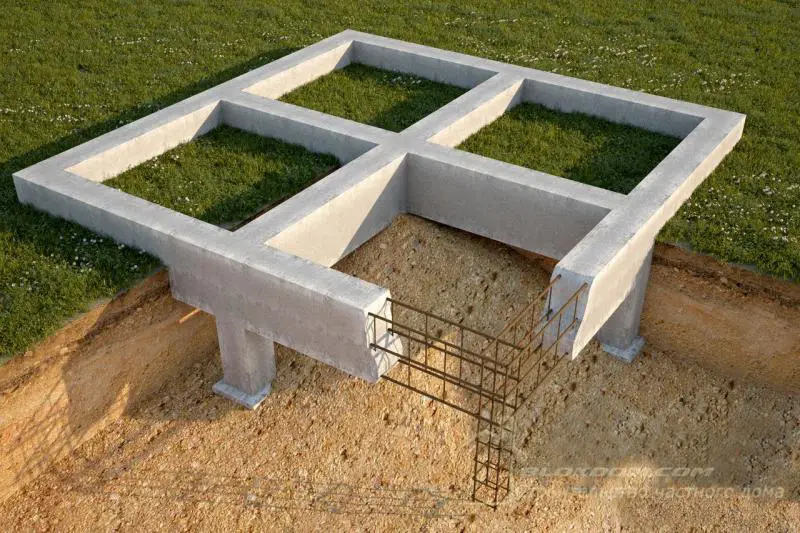

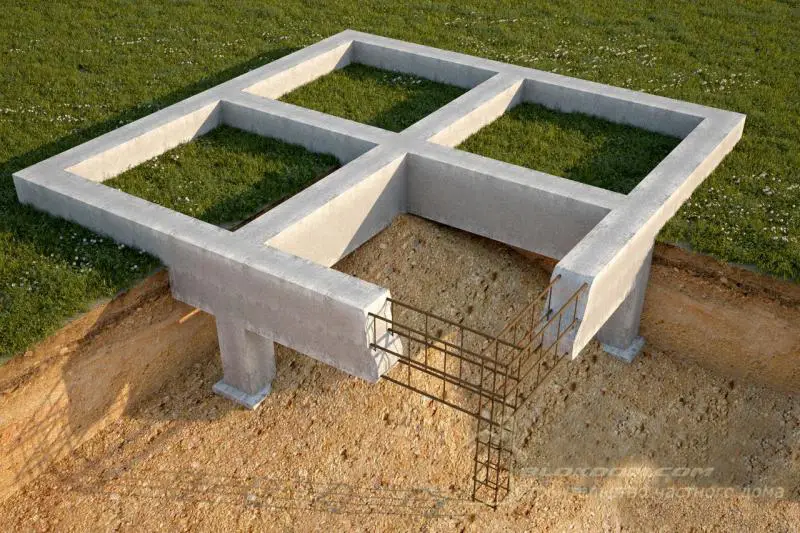

Installation of Screw Pile Foundation

Screw pile foundations are typically used for wooden structures. However, modern technologies now allow for the installation of load-bearing buildings up to four stories high. This is due to the increased strength of new screw pile types, each capable of supporting a static load of up to six tons.

To install a screw pile foundation, you need to:

- purchase screw piles;

- mark the area where the piles will be installed;

- drive them into the ground;

- secure the piles with concrete and weld on the caps.

Always buy screw piles from reliable manufacturers who guarantee strength and corrosion resistance. Attempting to make them yourself will likely result in a significantly worse outcome.

Specialized equipment resembling a larger motorized drill can be used to install the piles. However, surprisingly, even without such equipment, a couple of workers can install the piles using a special wrench.

The pile installation depth should not be less than 1.5 m. After installation, the structure is treated with a special anti-corrosion compound to protect metal components.

Technical and Economic Benefits

When properly installed, a screw pile foundation not only ensures a strong and durable structure but also results in substantial savings. After installation, you can be confident that a building on marshy soil will last at least 50 years. Since the piles are driven down to relatively solid soil and, thanks to their blades, achieve maximum contact area, there's no need to worry about settlement over the structure's lifetime.

The second major advantage is low foundation cost. The limited number of load-bearing elements reduces overall cost, and the foundation can be completed in just 3–4 days. Once the concrete has set, construction can begin immediately.

Relative disadvantages of this foundation type include the inability to build reinforced concrete or brick buildings on it, as well as unsuitability for rocky soil.

Need a renovation specialist?

Find verified professionals for any repair or construction job. Post your request and get offers from local experts.