Technology of Sandwich Panel Installation

The preparatory stage before installing sandwich panels involves preparing design and installation documentation. The package includes a layout diagram, specifications for all structural elements and their dimensions. Additionally, the installation documentation specifies the method of fastening panels to the metal frame, as well as the locations of connecting modules.

The preparatory stage before installing sandwich panels involves preparing design and installation documentation. The package includes a layout diagram, specifications for all structural elements and their dimensions.

Additionally, the installation documentation specifies the method of fastening panels to the metal frame, as well as the locations of connecting modules. Detailed drawings of all joints are attached to the design documentation. If architectural or custom elements are used in the wall structure, this must also be reflected in the design documentation.

The final step in preparation for sandwich panel installation is verifying that actual component dimensions match those specified in the design. Any dimensional discrepancies are compensated by adjusting wall rafters. Any uncorrected deviations will inevitably disrupt the panel layout pattern.

Hoisting Sandwich Panels

Installing sandwich panels requires the use of lifting equipment and machinery. Mechanical clamps are most commonly used. All clamps are divided into three types:

- a clamp that creates a through-hole in the panel for lifting;

- a specialized clamp that attaches to the panel's locking mechanism;

- a clamp operating on vacuum suction principle.

Special attention must be paid to lifting panels from pallets—here, it is crucial not to deform the joint. Openings left in panels after mechanical clamping are sealed with custom fittings. Safety straps (slings) must be used during lifting and must wrap around the panel. These straps are removed only immediately before final placement.

Panel Cutting and Drilling

Installation cutting of bonded sandwich panels is performed using snips and cold-working saws (e.g., manual circular saw or electric jigsaw). Excessive metal heating must be avoided during cutting and drilling, as it damages the anti-corrosion coating. Therefore, grinding tools and plasma cutting equipment are strictly prohibited during sandwich panel processing.

For small-scale cutting operations, manual metal snips or electric-powered snips are recommended. Despite their low throughput, the cutting quality far exceeds any automated process. In this case, both metal skins are cut separately.

Panel Fastening

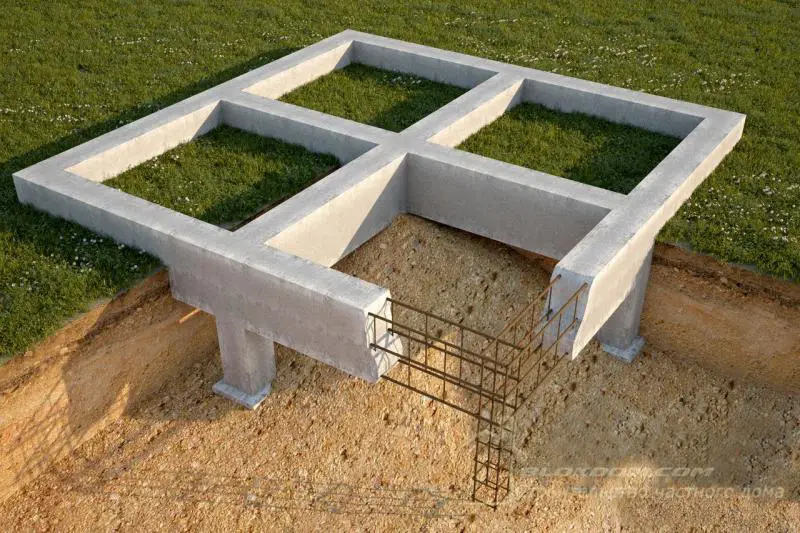

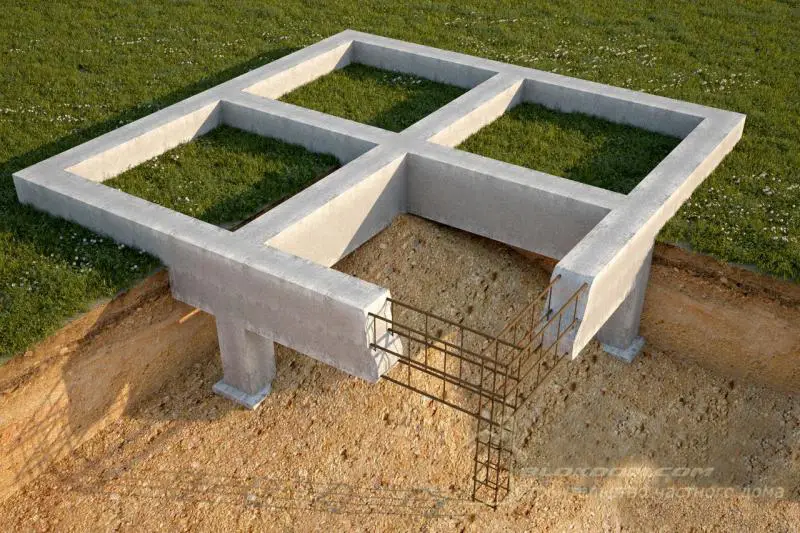

Panels must be fastened to a load-bearing structure, which may be made of metal or concrete. The type of fastener used depends on the structural material. For metal frames, special self-drilling screws with sealing washers made of compressed polyethylene or rubber must be used. The thread pitch must be selected according to the steel composition of the building frame.

If the building frame is made of monolithic concrete, sandwich panels are fastened using concrete anchors or chemical anchors. Special attention must be given to the quality of the expansion mechanism in fastening tools, and a pull-out test must be conducted before installation to determine anchor resistance.

Regardless of the building frame type or panel thickness, fasteners must be installed strictly perpendicular to the wall surface. Custom fittings are installed using a drill to create holes and a high-speed screwdriver to drive screws with compression washers to full depth, applying maximum torque.

The number of fasteners per square meter of wall is determined during the design phase by calculation. The following factors must be considered:

- wind load (depends on construction region and panel height);

- type of structure;

- panel location in the building (roof or facade).

Need a renovation specialist?

Find verified professionals for any repair or construction job. Post your request and get offers from local experts.