Gas Silicate Blocks

Gas silicate blocks have been widely used in private and industrial construction in Russia and worldwide for many years. As one of the most prominent representatives of this group of building materials, gas silicate blocks offer low cost compared to bricks and other small masonry units, as well as superior thermal insulation performance.

Gas silicate blocks have been widely used in private and industrial construction in Russia and worldwide for many years. As one of the most prominent representatives of this group of building materials, gas silicate blocks offer low cost compared to bricks and other small masonry units, as well as superior thermal insulation performance.

For builders, the main advantages include low cost compared to traditional materials, high construction speed, and ease of laying. This article explores the main types and benefits of cellular concrete.

Types of Gas Silicate Blocks

- Gas Concrete – one of the types of lightweight cellular concrete. It is an artificial stone with uniformly distributed closed air cells up to 3 mm in diameter. The main components of gas concrete are cement, sand, and specific gas-forming agents. Due to its high porosity, gas concrete belongs to the group of so-called 'warm' wall materials, with thermal conductivity significantly better than brick or traditional monolithic concrete.

- Porous Concrete – differs from gas concrete only in production method: air cells are formed by adding foaming agents. The main ingredients of porous concrete are cement, quartz, and lime.

- Gas Silicate – the direct ancestor of all cellular concretes. Produced via autoclave process. The recipe includes ground lime, crushed sand, and aluminum powder. Compared to gas and porous concrete, gas silicate has lower weight and superior thermal insulation.

Classification by Strength and Application

In gas silicate block production, three standard density limits are traditionally used: 400, 500, and 600 kg/m³. There is a direct correlation between density and strength.

Blocks with a density of about 400 kg/m³ are suitable only for internal partitions up to 3–4 meters in height. Higher walls are not recommended due to the risk of mechanical failure in lower rows.

Blocks with 500 kg/m³ density are the most popular among private builders. They are used for external load-bearing walls in houses up to three stories. Their excellent thermal resistance allows for reduced thickness of additional insulation to meet required thermal resistance values.

Blocks with densities of 600 kg/m³ and higher are widely used in industrial and civil construction, including buildings up to 75 meters high. Typically, gas silicate blocks are used in monolithic-frame construction for wall openings, followed by plastered or ventilated façade finishing.

Limitations of Gas Silicate Use

Due to its porous structure, gas silicate blocks are highly hygroscopic (absorb moisture from the environment). This factor imposes several construction limitations.

First, if blocks get wet from rain, they must be dried before installation, otherwise there is a risk of adhesive joint failure due to thermal expansion.

Second, prior to finishing interior spaces, internal vapor barrier must be installed. Otherwise, capillary moisture may penetrate the wall mass due to pressure differences between indoor and outdoor air.

Third, temperature limits apply. Gas silicate blocks are not recommended for use where operating temperatures exceed 400°C, especially in various exothermic industrial processes involving significant heat release.

Installation Procedure for Gas Silicate Blocks

While dimensions may vary slightly between manufacturers, the proportion between one side and the width of two bricks is maintained for ease of material calculation and wall thickness planning.

Blocks are laid on cement-based adhesive, prepared by mixing dry mix with water. The first course is critical for ensuring correct level and wall geometry. Subsequent courses are staggered by 30% or 50% to interlock joints.

If needed, certain courses can be reinforced by installing grooves on the top surface and embedding reinforcement bars. The adhesive applied before laying the next course should be spread with a trowel with a coarse comb-like profile.

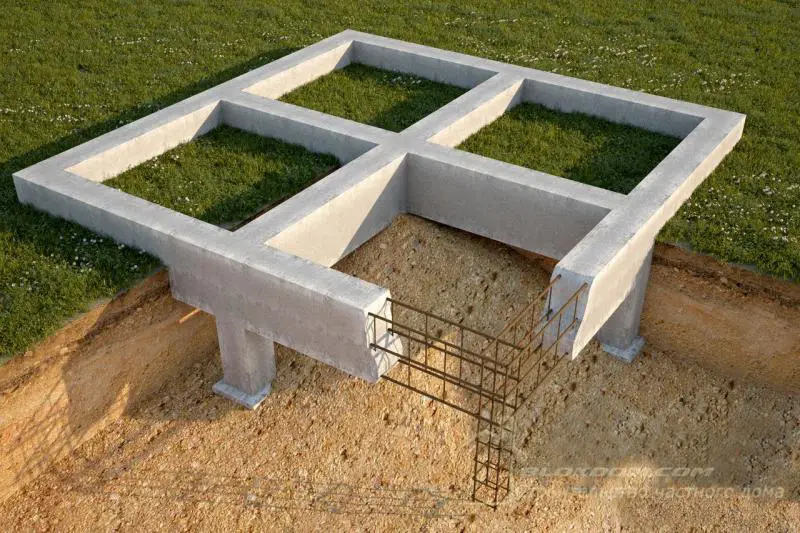

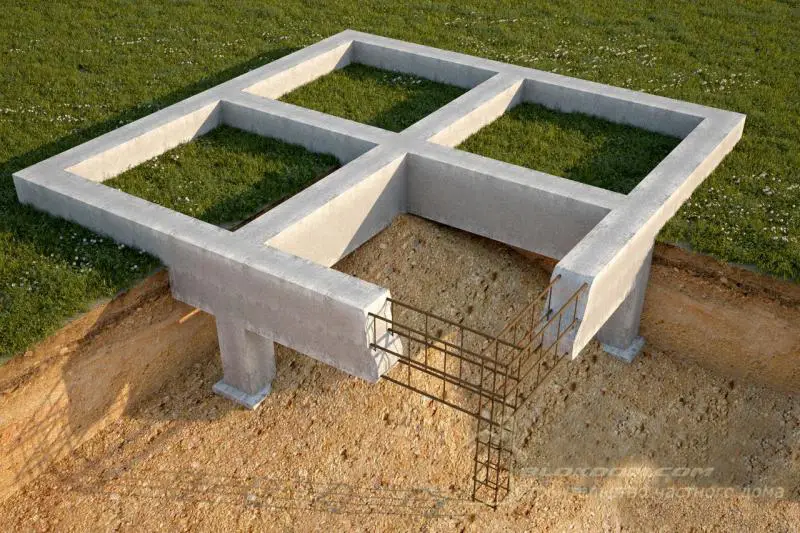

Between the foundation and the first block course, a waterproofing layer made of roofing felt or rubemast must be installed. Moisture can capillary draw into the porous structure, leading to permanently damp walls. Excessive moisture exposure accelerates degradation, especially under repeated freeze-thaw cycles.

Need a renovation specialist?

Find verified professionals for any repair or construction job. Post your request and get offers from local experts.