Installation and Fixing of Formwork

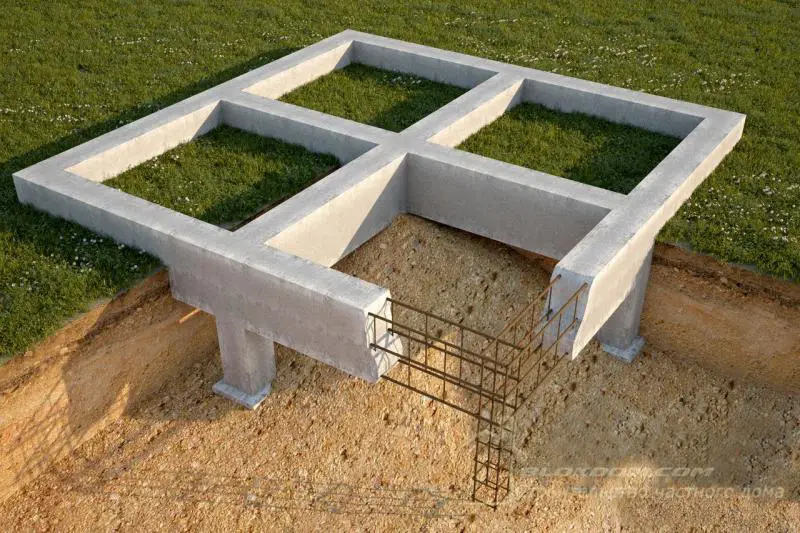

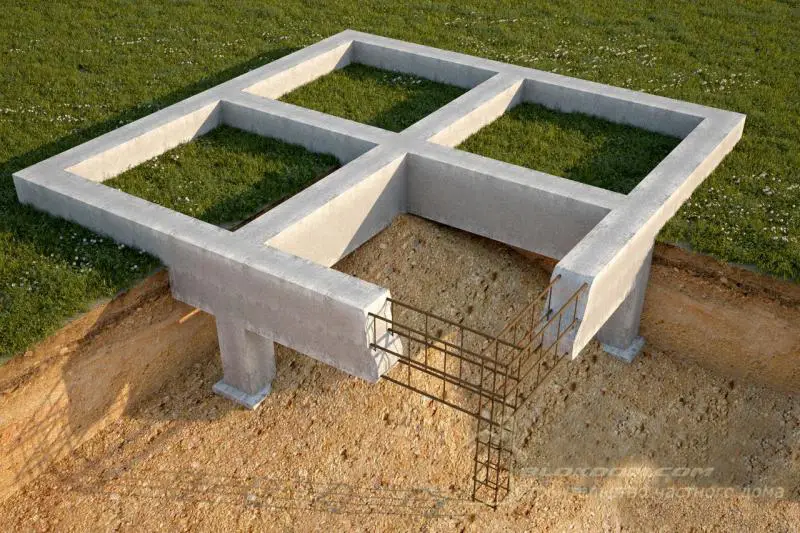

Formwork is installed on the ground part of the foundation, below the horizon, with the trench or pit itself serving as the mold. The formwork for the foundation must be strong and securely fastened; otherwise, its walls will burst under the poured concrete and the entire work will be ruined. The walls must not have gaps or holes that allow the cement paste to leak out.

Formwork used for a slab foundation experiences particularly high loads.

When building formwork for a strip foundation, remember to leave openings for future installation of water supply, sewage, and other utility lines. A wooden box of 200 x 200 mm is typically installed, with length matching the foundation width.

Materials for Formwork

Formwork can be made from various materials: metal, wood, moisture-resistant plywood, MDF panels, or plastic.

In the context of building a private home, reusable wooden formwork is traditionally used for pouring the foundation. It consists of panels made from tightly fitted boards, 25–40 mm thick. Softwood is preferred.

The side of the board that contacts the concrete must be carefully planed. Nails are driven into the smooth side and bent over to secure the horizontal battens. The battens are placed 1.5–2 m apart. Board width should not exceed 150 mm, as wider boards tend to develop gaps quickly.

Reusable, modular formwork is usually bought from other builders in the community or rented from a local craftsman. This encourages careful handling, although fastening is typically done with nails.

Securing Metal and Combined Formwork

Modular, reusable metal and combined formwork is secured using bolted ties and nuts. Long bolts are passed through pre-drilled holes in the panels. To allow reuse, the bolts are inserted into sleeves of appropriate diameter, which also act as width limiters for the future foundation.

Wrapping the bolts with paper can help prevent them from sticking to the hardened concrete, facilitating later removal and reuse.

Securing Wooden Formwork

Prepared panels made from tightly fitted boards are assembled into a box, fastened with wooden battens (approx. 50 x 50 mm). A wooden tie at the base maintains the required distance between walls, while a wooden cover is fixed at the top. Their length is determined by the foundation width, and spacing matches the vertical battens used in the assembly.

Recently, wooden formwork panels have been reinforced with metal supports and ribs, improving strength and extending service life and reusability. It is also recommended to line the inside of the formwork with polyvinyl chloride (PVC) film before pouring concrete. This enhances watertightness and prevents wood from absorbing excess moisture.

Need a renovation specialist?

Find verified professionals for any repair or construction job. Post your request and get offers from local experts.