Insulating Floors in Country Houses: 6 Tips from Experts

First of all, you need to select the right insulation. There are several general requirements for it that must be met regardless of floor construction: high efficiency, reliability, safety, ecological safety, and durability.

The most important factor is the excellent thermal insulation capacity of the insulation material, i.e., its thermal conductivity. The lower the thermal conductivity, the thinner layer is required to protect the house. Modern insulating materials have a thermal conductivity coefficient of no more than 0.05 W/(m·K), ensuring their effectiveness.

Some types of thermal insulation can only be used with reliable fire protection (e.g., under a concrete layer), but today professionals prefer modern non-combustible insulation materials. Among them are stone wool, which is fire-resistant like the stone from which it's made: its fibers can withstand temperatures up to 1000 degrees Celsius. Insulation based on this material will last at least 50 years.

High-quality insulation allows water vapor to pass through so that the structure 'breathes', but at the same time does not absorb or retain moisture. This is because water vapor entering the pores of thermal insulation reduces its properties. Materials with open porosity are most effective in allowing water vapor to pass through. It is better to choose products made from natural materials, which should have ecological certificates confirming their safety.

Tip #2: Choose Insulation According to Floor Type and Its Characteristics

Different types of floors have specific characteristics that must be taken into account when selecting and installing thermal insulation materials. In a country house, the floor is usually laid either above a basement on joists or directly on the ground. The first option is more common. When building a floor on wooden joists, thermal insulation does not experience loads, so lightweight insulating materials can be used. If the floor is constructed directly on the ground with a screed over the insulation, then rigid plates of high strength are required. For any floor type, the thickness of the insulation layer is determined by calculations based on the thermal protection properties of the material and other conditions.

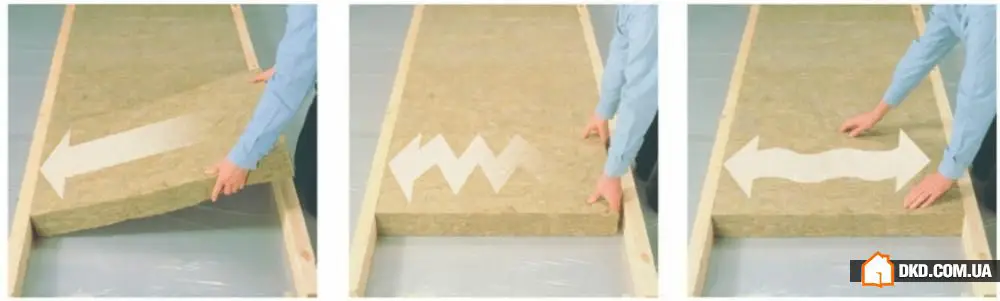

Tip #3: Use Insulation Materials with Flexible Edges When Insulating Floors on Joists

The general structure of such floors looks like this: wooden beams (joists) are laid on load-bearing beams, and then floor boards are installed. Insulation is placed between the joists, and it is covered with boards from below. Special plates made of stone wool designed for frame structures are very convenient during installation. These plates have a flexible edge (Flexi technology). These products do not require cutting or precise fitting: the distance between joists is less than the size of the plate, so it fits tightly against the joists after insertion. Note that you should insulate all structures, not just the floor.

Tip #4: Pay Special Attention to Insulating Floors Over Cold Basements

According to modern requirements, the thickness of insulation for floors over unheated basements must be at least 100 mm. It is recommended to start the floor insulation from this area. Usually, floors over basements or ground floors are built on wooden joists. When insulating such floors, wooden strips are installed with a spacing that matches the size of the insulation plates, which are then placed in the gap between the strips and secured with wooden battens or mesh, followed by covering with boards.

For insulating reinforced concrete slabs from the basement side, rigid insulation plates are fastened using plastic anchors. A special case, quite common in private house construction, is insulating the basement floor during operation. In this case, the wooden floor does not need to be dismantled.

Tip #5: For Ground Floor Insulation, Choose Special Materials for Screed

The first stage of work for insulating such floors is leveling the base and laying sand or gravel fill. After concrete preparation, a layer of waterproofing made from rolled bitumen or bitumen-polymer material is applied. Then the insulation is laid on this layer, followed by a concrete screed. The finished floor covering is placed on top of the screed.

In this type of construction, insulation is exposed to loads, so it is necessary to use materials with high compressive strength. Usually, these are rigid plates measuring 100x60 cm made from stone wool with a thermal conductivity coefficient of only 0.038 W/m·K. This material is durable, non-combustible, long-lasting, and environmentally safe.

Tip #6: Don't Forget to Provide Vapor Barrier for the Insulation

A vapor barrier layer must be placed on top of the insulation. This protects it from moisture vapor coming from the room. For this purpose, it is best to use special vapor barrier film. It is laid with an overlap of at least 100 mm, and the seams are sealed with special tape or adhesive to ensure tightness. An air gap should be left above this layer.

*On the cover: Irina Krivtsova's project.

Need a renovation specialist?

Find verified professionals for any repair or construction job. Post your request and get offers from local experts.

You may also like

More articles:

20 effective ways to divide a room

20 effective ways to divide a room New Furniture Design: Modular Shelves for Living Room

New Furniture Design: Modular Shelves for Living Room 16 effective ways to decorate a bathroom in the mid-20th century style

16 effective ways to decorate a bathroom in the mid-20th century style Modern Concept of Open-Plan Home by Klopf Architecture

Modern Concept of Open-Plan Home by Klopf Architecture 18 Outstanding Kitchen Designs from the Middle of the Century for All Vintage Interior Enthusiasts

18 Outstanding Kitchen Designs from the Middle of the Century for All Vintage Interior Enthusiasts Take a Look Inside Amazingly Functional Apartments of 8 Square Meters

Take a Look Inside Amazingly Functional Apartments of 8 Square Meters Grow a Tree in Your Interior

Grow a Tree in Your Interior How to Use LED Lighting in Modern Interior Design

How to Use LED Lighting in Modern Interior Design