Communication Nightmare: How We Defeated 7 Types of Pipes in a Stalin-era Apartment and Saved 400 Thousand

Challenges and difficulties during the renovation that you need to know about

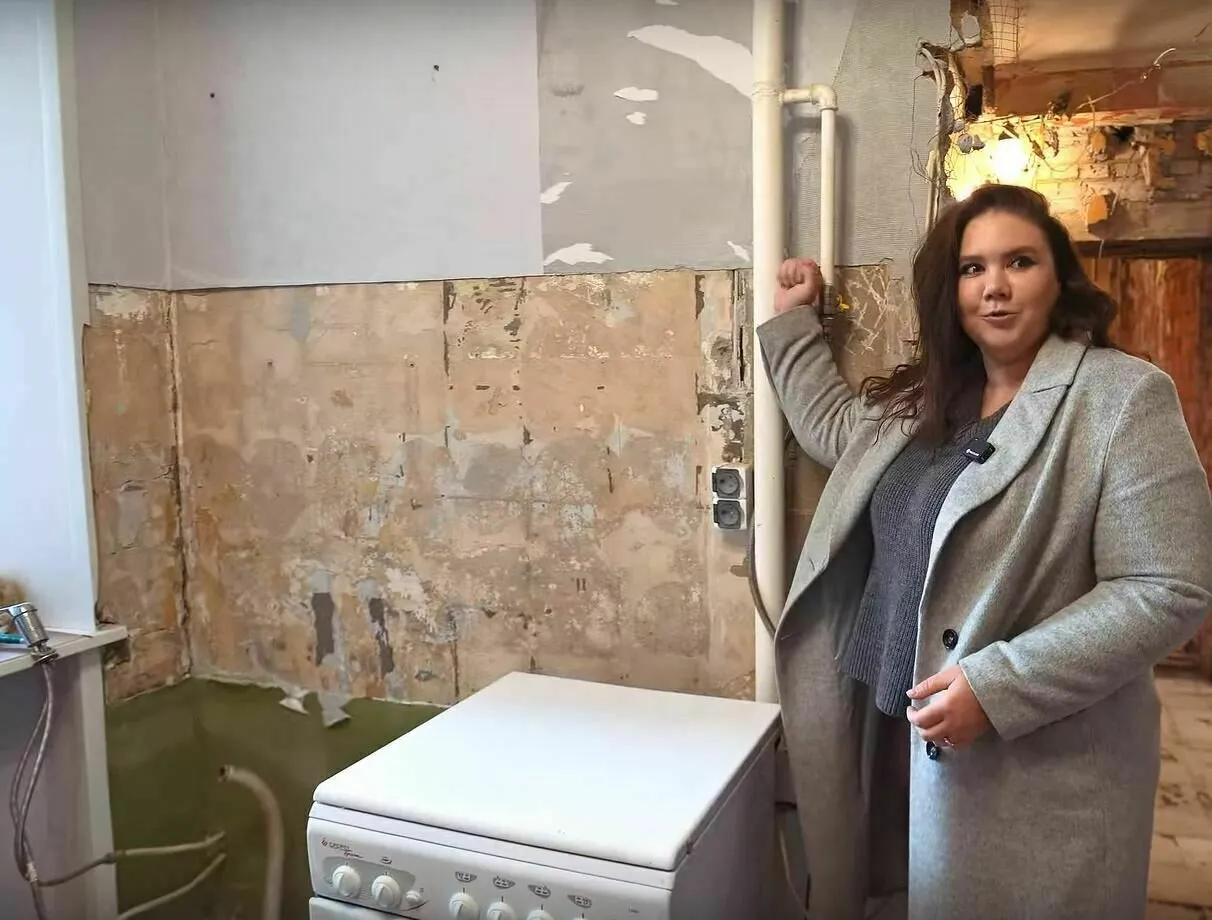

In our second episode of 'The Renovation Movement' with Ksenia Shahmatova, we encountered a true engineering nightmare — an apartment in a Stalin-era building of series 205, where an incredible 'zoo' of utilities had accumulated over the decades. Seven different types of pipes, wiring from three generations, cast iron radiators weighing as much as a small refrigerator, and a giant gas 'royal pipe' with a diameter of 7 centimeters proudly rising on the kitchen wall. This is exactly the case when plumbers shake their heads and offer to add 30% to the estimate. But we found unconventional solutions that not only saved the interior's aesthetics but also allowed us to save around 400 thousand rubles on renovation. We share secrets you won't find anywhere else.

Watch all episodes of The Renovation Movement here:

- Episode 1: We Bought a Dead Stalin-era Apartment – What Went Wrong?

- Episode 2: Relocation: Which Solution Saved Our Stalin-era Apartment?

- Episode 3: Expensive Renovation Mistakes.

- Episode 4: How to Stay Within 3 Million? Finishing Work.

Main Points from the Article:

Engineering systems in a Stalin-era apartment consisted of 7 different types of pipes, some over 70 years old;

Smart modernization of utilities without total replacement saved around 400 thousand rubles;

There are legal ways to hide almost any pipes without violating safety standards;

We solved the problem with the gas 'royal pipe' using an innovative kitchen cabinet;

Replacing critical sections instead of a complete overhaul of all systems — the key to savings.

Seven Circles of Communication Hell: What We Encountered

When we first stepped into the apartment, we didn't expect to face such a scale of technical problems. Let's break down the engineering 'zoo' of this Stalin-era building:

1. The Royal Gas Pipe (1950s)

The kitchen's dominant feature — a steel gas pipe with a diameter of about 7 cm that boldly crosses the entire wall. 'Not just any gas pipe, but a royal one,' Ksenia described it. According to safety standards, it cannot simply be embedded — access for inspection must always be maintained.

2. Cast Iron Sewerage with Seniority (1950s)

Heavy pipes weighing up to 40 kg per meter. Coated with layers of paint and rust for years, with dangerous cracks and leaks at connection points.

3. Steel Water Supply with Critical Lime Scale (1950s–70s)

The internal diameter of the pipes has decreased by half in places due to deposits. The water pressure on upper floors was so weak that using a shower became a true test of patience.

4. Aluminum Wiring Without Grounding (1960s)

We found bare wire connections in several places — potential fire hazards. Sockets were placed in the most unexpected locations without any logic.

5. Cast Iron Radiators Weighing 80–100 kg Each

Over the years, a thick layer of deposits formed inside, reducing heat output by 40–50%. Turning the adjustment valve either caused overheating or complete lack of heat.

6. Copper 'Artistic' Plumbing (1990s)

Remnants of 90s renovations: copper pipes laid on top of plaster in zigzag patterns, creating 'engineering art' on the walls.

7. Plastic Pipes from Early PVC (Early 2000s)

Faded in the sun, cracked, with leaking joints — a sign of early experiments with plastic utilities.

As Ksenia Shahmatova notes: 'These are all the renovations that were layered on top of each other over seven decades. Instead of removing old pipes, they just ran new ones nearby. In the end, we got a true museum of plumbing evolution!'

The First Challenge: The Gas 'Royal Pipe' — How We Tamed It

A 7 cm diameter gas pipe became our first and most challenging test. Simply covering it with a box is not allowed — that violates gas safety rules.

Standard solutions and their drawbacks:

- A box with grilles — looks unattractive and collects dust;

- Decorative screen — doesn’t cover the entire pipe;

- Going without gas — requires approvals and increases electric power allocation.

Our Innovative Solution:

We developed a 'smart access' system through a false wall and kitchen cabinet-cupboard:

The lower part of the pipe is hidden in kitchen cabinets with access through them.

The upper part is covered by a special cabinet-cupboard: 'Have you ever seen something like this trendy item that's gaining popularity now? It’s a kind of cabinet with doors. I want to make such a cabinet,' Ksenia explains.

Wall extension by 20 cm for a false construction: 'The first thing that will happen here is the wall expands by 20 cm. So there'll be more space here. We’ll cover this entire wall with gypsum board, making a false wall with access!'

This approach not only solved the technical issue but also created extra space for kitchen appliances. Savings: around 70 thousand rubles compared to a full gas switch-off and switching to an electric stove.

The Second Challenge: Water Supply and Sewerage — A Surgical Operation Instead of Full Replacement

Initial assessment by plumbers: full replacement of all pipes with relocation of risers — 150 thousand rubles. But we took a different path.

Our approach with selective replacement:

Diagnostics of pipe condition using an endoscopic camera. We found that 70% of the cast iron sewerage was in good condition — only joints and outlets needed replacement.

A hybrid system — we kept the main cast iron risers (they'll last another 50 years), but replaced critical joints with modern PVC pipes with compensating fittings.

Chemical cleaning of water supply pipes instead of full replacement. A special compound removed lime deposits inside steel pipes, restoring normal water pressure.

Local replacement of faulty copper pipe sections with polypropylene using special adapters.

Result: Savings of approximately 100 thousand rubles while maintaining system reliability. As Ksenia notes: 'You don’t always have to replace everything completely. Sometimes it's smarter to do selective repair, keeping what still lasts decades.'

The Third Challenge: Heating System — How to Modernize Without Demolishing

Cast iron radiators in a Stalin-era apartment are true monsters weighing up to 100 kg each. Replacing them with modern aluminum would cost around 120 thousand rubles including labor. But we found a more elegant solution.

Our approach to heating modernization:

- Cleaning radiators with a special acid-based solution instead of full replacement. The procedure removed multi-year deposits and restored heat output to 90% of the original.

- Installing thermostats on existing radiators — this allowed precise temperature control in each room.

- Decorative radiator grilles with a directed heat flow effect — this increased heating efficiency by 15–20%.

- Painting radiators with heat-resistant paint to match wall color — this visually integrated the heavy units into the interior.

Savings: around 90 thousand rubles while improving energy efficiency of the heating system.

The Fourth Challenge: Electrical Wiring — A Quiet Safety Threat

Aluminum wiring from the 1960s represented a real safety hazard. There was no compromise here.

Our solution:

Full replacement of wiring with copper wire matching modern loads.

Designing a well-planned socket layout — following the principle of 'one socket per square meter'. 'In our projects, we usually have one socket per 1 m² — it may sound strange. Sockets are rarely single, often there are two or three in one spot,' Ksenia explains.

Installing a modern electrical panel with differential circuit breakers for each consumer group.

Laying wiring in conduit for additional protection.

Interesting fact: we discovered existing pre-war electrical wiring in cloth insulation inside the walls! These artifacts were carefully removed and handed over to a museum.

In this case, full replacement was the only safe solution. But thanks to a comprehensive approach and combining work with other renovation stages, we saved around 40 thousand rubles on installation.

The Fifth Challenge: Ventilation — An Invisible Problem in Old Buildings

In the Stalin-era apartment, we encountered a nearly non-functional ventilation system. Ventilation ducts were clogged with years of dust, construction debris, and even bird nests.

Our approach:

Professional cleaning of ventilation ducts instead of installing forced ventilation.

Restoring natural air circulation by correctly installing supply valves in windows.

Installing low-noise exhaust fans with humidity sensors in bathrooms.

Creating a system of micro-supply valves directly in the rooms.

Savings: around 100 thousand rubles compared to installing a full forced ventilation system with heat recovery.

Six Principles for Working with Engineering Systems in Old Buildings

Based on our experience, we've formulated six key principles to help deal with any communication nightmare in old buildings:

Diagnostics Before Demolition

Don’t rush to demolish everything down to the foundation. Thorough diagnostics will help preserve functional elements.Selective Replacement Instead of Total

Replace only critical sections. This saves not just money but also time.Combining Old and New

Use modern technologies to upgrade existing systems.Hiding Instead of Removal

If an element can’t be removed, make it part of the design.Comprehensive Approach to Work

Combine different types of work to save on installation/removal.Compliance with Technical Standards and Rules

Savings should not come at the cost of safety.

Specific Solutions for Each Type of Utility

For Gas Pipes:

- False wall with access system through cabinets and sliding cabinet;

Decorative boxes with ventilation grilles;

Moving the gas stove to minimize visible pipe sections.

For Water Supply Pipes:

Chemical cleaning instead of full replacement;

Hidden installation in gypsum board structures;

Using decorative chrome overlays for visible sections.

For Sewerage:

Keeping cast iron risers with replacement of problematic sections;

Installation in niches with inspection hatches;

Noise insulation of pipelines to reduce noise.

For Electrical Wiring:

Full replacement of aluminum wiring with copper;

Rational socket placement (one per square meter);

Using modern protective circuit breakers.

Flushing instead of replacement;

Using decorative screens;

Installing thermostats to improve energy efficiency.

Cleaning and restoration of existing ducts;

Installing low-noise fans with sensors;

- Ensuring proper air supply.

Final Result: Saving 400 Thousand Without Compromising Quality

A comprehensive approach to engineering systems in our Stalin-era apartment allowed us to save around 400 thousand rubles:

70 thousand — on solving the gas pipe issue;

100 thousand — on water supply and sewerage;

90 thousand — on the heating system;

40 thousand — on electrical wiring;

100 thousand — on ventilation.

While we weren’t just saving money — we found solutions that made utilities more efficient, reliable, and aesthetically pleasing.

As Ksenia Shahmatova summarizes: 'The old housing stock is not a problem, but a challenge that can and must be accepted. With the right approach, even the most neglected engineering nightmare can become a functional and beautiful system that will last decades.'

And remember: renovating in old buildings is always an archaeological dig with elements of an engineering quest. Prepare for surprises, stock up on patience, and definitely involve professionals to diagnose the condition of engineering systems before starting work. This will save not only money but also nerves!

Full video of the second episode:

Need a renovation specialist?

Find verified professionals for any repair or construction job. Post your request and get offers from local experts.

You may also like

More articles:

Interior by Zodiac Sign: How to Decorate Your Home in the Age of Aquarius

Interior by Zodiac Sign: How to Decorate Your Home in the Age of Aquarius How Colors in the Apartment Affect Mood: Analyzing Each Shade

How Colors in the Apartment Affect Mood: Analyzing Each Shade The Incredible Story of the Morozov Dynasty, Who Built a Textile Empire

The Incredible Story of the Morozov Dynasty, Who Built a Textile Empire House on Kotel'nicheskaya Embankment

House on Kotel'nicheskaya Embankment Charity of Russian millionaires: how the Morozovs built hospitals and changed Moscow's face

Charity of Russian millionaires: how the Morozovs built hospitals and changed Moscow's face Tragic Ending: How the Owner of a Luxurious Mansion, Alexei Morozov, Died Without Money for Transportation

Tragic Ending: How the Owner of a Luxurious Mansion, Alexei Morozov, Died Without Money for Transportation Before and After: From a Separate Diminished Bathroom to a Beautiful Light Interior

Before and After: From a Separate Diminished Bathroom to a Beautiful Light Interior Real Example: What to Consider When Renovating an Old Building

Real Example: What to Consider When Renovating an Old Building