Roll-on Waterproofing Roofing

Among the wide range of modern solutions for flat roof waterproofing, it's hard to find a more widespread method than roll-on bituminous membranes. Flat roofs of residential, industrial, and commercial buildings have been covered with 'descendants' of ruberoi and rubemast for many years. Roll-on bituminous waterproofing is applied to the roof base, which may be a layer of rigid mineral wool or cement-sand screed. Recognized market leaders in roll-on waterproofing have long been companies 'TechnoNIKOL' and 'Icopal'. Each offers a wide range of roll-on membranes.

Among the wide range of modern solutions for flat roof waterproofing, it's hard to find a more widespread method than roll-on bituminous membranes. Flat roofs of residential, industrial, and commercial buildings have been covered with 'descendants' of ruberoi and rubemast for many years.

Roll-on bituminous waterproofing is applied to the roof base, which may be a layer of rigid mineral wool or cement-sand screed. Recognized market leaders in roll-on waterproofing have long been companies 'TechnoNIKOL' and 'Icopal'.

Each offers a wide range of roll-on membranes. Flagship products for both companies are 'TechnoElast' and 'VillaFlex'. Both are bituminous membranes reinforced with a layer of glass fabric.

Advantages of Roll-on Roofing

Undoubtedly, for any roof, the most important parameter is its service life without repairs: the longer it is, the more attractive the structure becomes for the end customer. The integrity of the waterproofing membrane in roll-on materials is achieved through reinforcement of the bitumen layer.

Reinforcing elements in most roll-on materials are glass mat, glass fabric, or polyester. Of these three, polyester is clearly the best due to its flexibility and resistance to temperature fluctuations in the external environment. Polyester retains its flexibility and does not crack down to -35 degrees.

Any of the mentioned materials is inorganic, inert to moisture, does not degrade or rot. When selecting a waterproofing material, always compare tensile and bending strength on a beam.

Main advantages of roll-on roofing membranes are:

- high frost resistance and mechanical strength;

- easy cutting and installation in hard-to-reach areas;

- resistance to UV radiation from sunlight;

- absolute watertightness.

Installation Process for Waterproofing

As previously mentioned, bituminous materials are applied to the roof surface by heating with a propane torch, which increases their adhesive properties.

The base surface may be additionally treated with a bituminous primer coating to improve adhesion. Heating is performed using a propane torch, capable of reaching flame temperatures up to 600 degrees.

The waterproofing membrane for flat roofs must extend over all vertical roof penetrations: parapets, embedded fittings for heavy equipment, advertising panels, etc. To ensure shrinkage-free performance and secure fixation, a perimeter compression strip (also known as edge flashing) is used at these roof areas. It runs along the entire perimeter of vertical roof outlets and is fastened with self-tapping screws, ensuring reliable membrane compression.

Need a renovation specialist?

Find verified professionals for any repair or construction job. Post your request and get offers from local experts.

You may also like

More articles:

Electrical Water Heater: Types and Construction Features

Electrical Water Heater: Types and Construction Features How to Choose an Electric Water Heater

How to Choose an Electric Water Heater Heating a Country House by Yourself

Heating a Country House by Yourself How to Replace an Electrical Outlet

How to Replace an Electrical Outlet Pipe Insulation

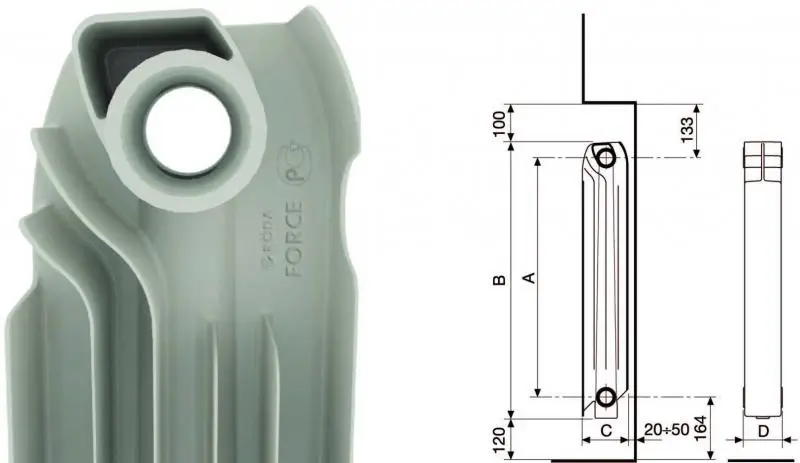

Pipe Insulation How to Choose a Heating Radiator

How to Choose a Heating Radiator Off-grid Power Supply System for a Country House

Off-grid Power Supply System for a Country House Installation of Heating Radiators by Yourself

Installation of Heating Radiators by Yourself