Insulation of the Roof with Your Own Hands

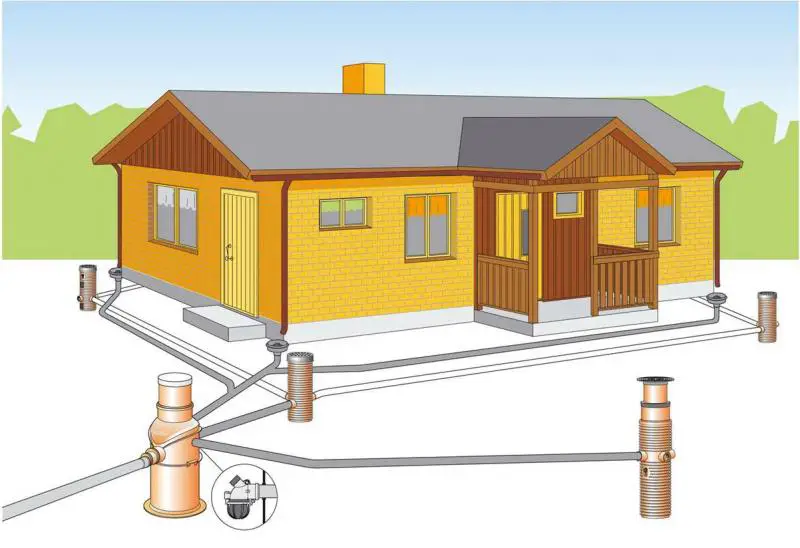

Before addressing the issue of roof insulation, it's essential to classify roofs based on their installation method and materials used. In general, roofs can be divided into pitched and flat types. Pitched roofs include various modifications of single-, double-, and four-pitched roofs, as well as gabled, mansard, and pyramidal structures.

Flat roofs with a slope of no more than 5-6% are used primarily in industrial and commercial buildings, where practicality takes precedence over aesthetics.

Insulating a Pitched Roof

Insulation of a pitched roof is achieved by installing mineral wool panels or mats made from glass fiber or basalt rock in the space between rafters. Additional components of a pitched roof structure include vapor barrier film and breathable waterproof membrane. These protect the insulation from excessive moisture from both inside the building and from outside.

When choosing the form of insulation material for a pitched roof, note that since integrity and absence of through joints or thermal bridges are critical in any insulation layer, rolled materials are preferred in this construction.

However, panels, despite having more transverse joints that could potentially be weak points in the roof structure, offer slightly better thermal conductivity performance than rolled materials. This fact favors the use of panel-based solutions in pitched roofs. In practice, both types of materials are used in the described construction.

Insulating a Flat Roof

Installation of mineral wool panels on flat roofs is carried out over a previously laid slope made from foam concrete or cement-sand screed. Typically, the roof's cross-section includes two layers of glass fiber or basalt panels. The first (lower) layer has a density of 60–90 kg/m³ and compressive strength of approximately 20 kPa, performing the primary insulation function. It constitutes a significantly larger portion of the total insulation mass than the upper layer (by 2–3 times).

The second layer, laid over the first, has a density of 120 kg/m³ or higher and a compressive strength of 60–70 kPa. Its main function is to protect the lower layer from mechanical damage and impact. During operation, flat roofs are exposed to snow loads, and personnel often walk on the glass fiber panels that serve as the base for the waterproof membrane, especially when equipment is installed on the roof.

Any damage to the structural integrity of the mineral wool will inevitably lead to failure of the waterproofing material in that area, resulting in roof leaks, damage to interior finishes, and significant financial costs for repair.

Need a renovation specialist?

Find verified professionals for any repair or construction job. Post your request and get offers from local experts.