Roof Insulation Technology

Since the roof is a building's protective structure directly exposed to the external environment, it regularly experiences severe temperature fluctuations. For example, indoor temperature may be +24°C, while outdoor temperature drops to -30°C. A temperature difference of 54°C across a 40 cm thick roof structure creates high stress on every component of the roofing system.

To mitigate the harmful effects of such temperature swings, every roof must be insulated. Insulation is especially critical for metal roofing, standing seam roofs, metal tiles, and profiled sheets.

If insulation type and thickness are chosen with full responsibility, significant savings on heating and air conditioning costs can be achieved. In Russia, thermal calculations and determination of thermal resistance for building structures are standardized in the regulatory document titled "Design of Thermal Protection for Buildings." This document provides a comprehensive set of guidelines used by designers when selecting insulation solutions and is accessible to anyone with basic mathematical skills.

Typically, two types of insulation materials are used for roofing: rigid boards made of glass wool or basalt wool for flat roofs, or flexible rolls and boards of the same materials for non-load-bearing framed structures in sloped roofs.

An additional function of insulation in roofs is sound insulation — particularly important for metal roofs, whose resonant properties can turn even ordinary rain into a full-scale artillery barrage.

Insulating Flat Roofs

Roof repairs on flat roofs often begin with removing the old roofing layer, including the insulation material that serves as the base for the waterproofing membrane.

If a cement-sand screed is planned as a protective layer over the insulation on a flat roof, no fasteners are used during mineral wool installation. However, if the wool is installed in two layers and the second, upper layer is intended to serve as the protective layer, special flat-topped fasteners of appropriate length must be used.

The length of the roofing dowel must allow it to penetrate through the entire mineral wool layer and embed into the base (e.g., concrete slab) by at least 50 mm. The core of such fastener must be metallic and never plastic.

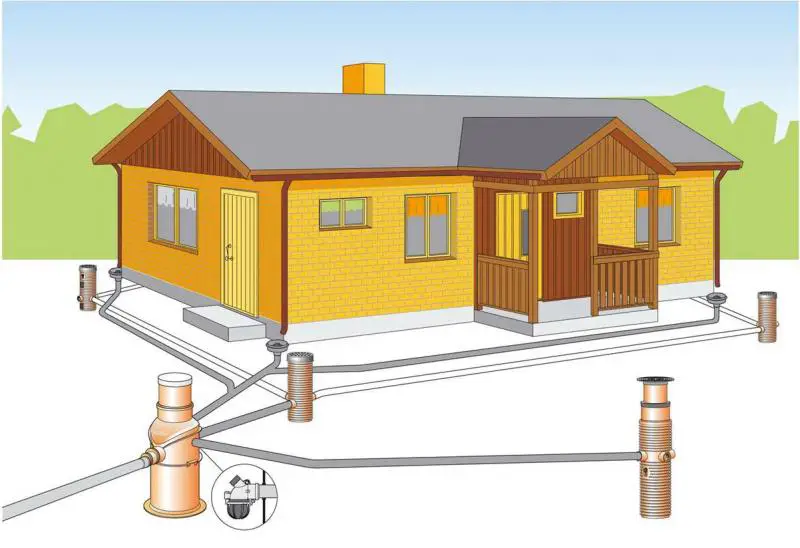

Insulating Sloped Roofs

Sloped roofs are traditional framed structures, where low-density insulation is installed in the space between rafters. In this context, rafter spacing is crucial. It ranges from 0.6 m to 1.2 m and directly affects the speed of insulation installation, the need for cutting, and the amount of waste (offcuts).

An optimal spacing of 600 mm between rafters, with a clear span of 550 mm, allows standard 565 mm or 600 mm wide glass wool boards to be installed snugly without cutting.

There is no definitive preference between using rolls or boards in sloped roofs — each has its advantages. Roll insulation provides a uniform thermal blanket across the entire roof slope with minimal or no transverse joints. Boards, on the other hand, are more rigid and elastic, ensuring long-term performance in the roof structure. Additionally, boards offer slightly better thermal conductivity.

Need a renovation specialist?

Find verified professionals for any repair or construction job. Post your request and get offers from local experts.