There can be your advertisement

300x150

Assembly and Installation of Log Cabin: From Processed Round Timber

The selection of timber must be meticulous: logs should be calibrated, have a consistent diameter throughout their length, and feature pre-cut grooves and notches. Additionally, logs must be free from defects such as blue stain (indicating decay), signs of wood-boring insects, mold, knots, large cracks or splits, and must have a solid heartwood. Manufacturing a log cabin from pre-selected, factory-processed, and precisely milled timber ensures rapid assembly and simplified installation.

Log Selection

Logs should be calibrated, have a consistent diameter throughout their length, and feature pre-cut grooves and notches.

Photo 1 – Log cabin made from processed round timber

Beyond technical preparation for fast assembly, logs must be free of defects:

- no blue stain, which indicates decay;

- no signs of wood-boring insects;

- no mold infestation;

- no knots;

- no large cracks or splits;

- with solid heartwood.

Photo 2 – Selecting logs

Manufacturing a log cabin from pre-selected, factory-processed, and precisely milled timber ensures rapid construction and simplified installation.

Advantages of log cabins made from processed round timber include:

- attractive design;

- eco-friendliness;

- durability;

- efficient thermal retention;

- ability to maintain a comfortable indoor microclimate;

- capability to realize complex architectural projects.

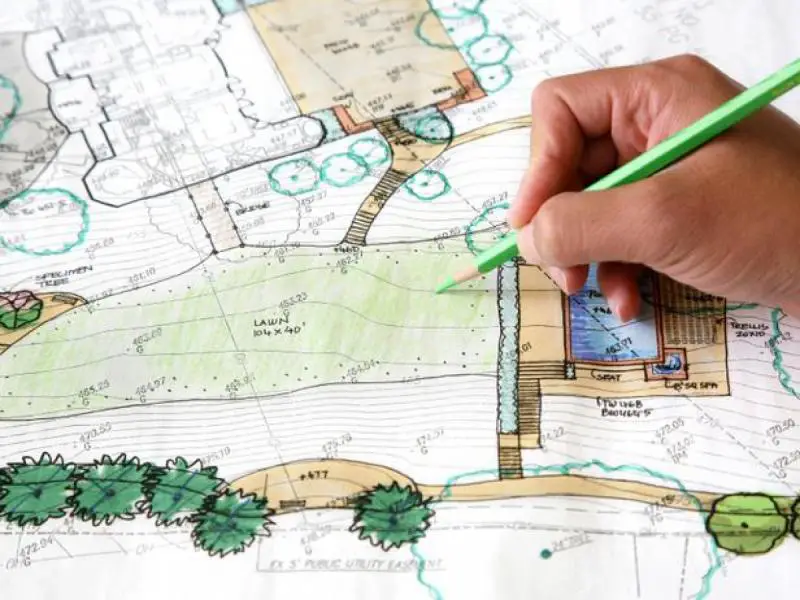

Volume Calculation

An accurate calculation of the required timber volume for log cabin construction can be performed by a qualified design specialist. When ordering a detailed construction project, you receive precise calculations specifying exact material quantities, dimensions, and structural parameters.

Materials listed in the specifications can later be purchased independently or entrusted to professional builders.

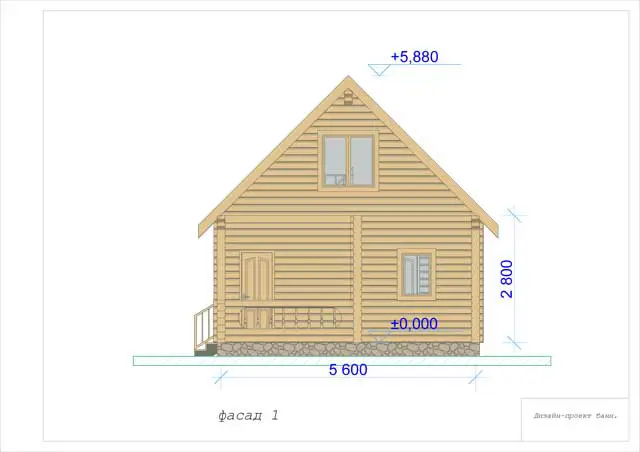

Photo 3 – Volume calculation for logs is supported by a cabin design

Project specifications also include details on fastener quantities and types, roofing materials, and interior and exterior finishing supplies.

Assembly of Log Cabins from Processed Round Timber

Photo 4 – First log course

Self-assembly of log cabins follows a defined sequence:

- foundation laying;

- installation of waterproofing;

- laying log courses with intercourse insulation;

- cutting openings;

- construction of the roof structure;

- chinking.

Photo 5 — Chinking

After completing the settling process, re-chink if natural moss or traditional hemp was used as the sealing material.

IMPORTANT! Exterior cladding is not required if the cabin is built from processed round timber. However, treating logs with antiseptics, fire retardants, and protective coatings is mandatory.

Installation of Log Cabins from Processed Round Timber

Log cabin installation using processed round timber can follow multiple techniques, such as 'in lap' or 'in notch'.

Photo 6 – 'In Lap' technique

Photo 7 – 'In Notch' technique

A strong foundation must be prepared in advance, selected based on building dimensions: monolithic (slab) or pile (column) type.

Photo 8 – Slab foundation

Photo 9 – Pile foundation

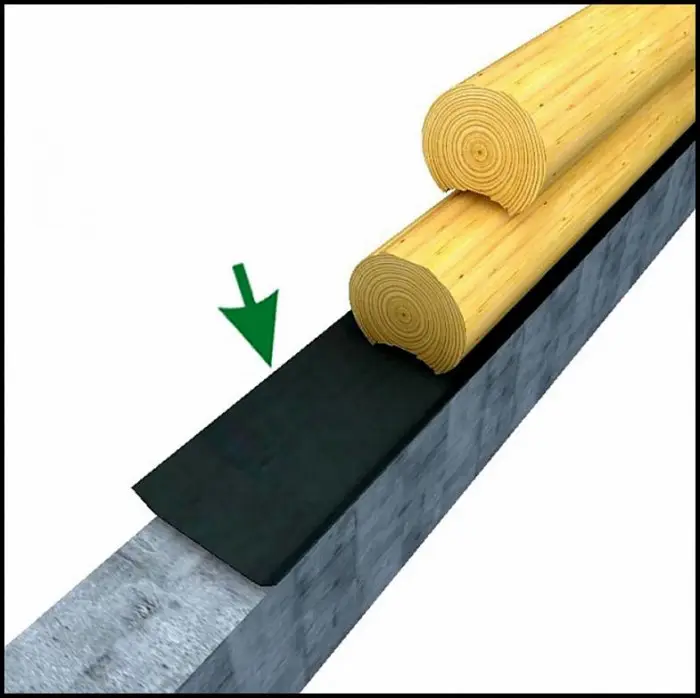

IMPORTANT! The first log course must be separated from the foundation by a waterproofing layer. This layer consists of roofing felt (or equivalent), underlayment boards (20–30 cm wide, 5–7 cm thick), and a sealing layer placed on top before laying the first course.

Inter-course insulation can be any material: moss, hemp, or composite filler.

Photo 10 — Inter-course insulation

Log courses are connected using wooden pegs or metal dowels, according to traditional joinery techniques.

Drilled holes for pegs follow a staggered pattern along the log length, spaced 1.5–2 meters apart. Peg length is selected based on log diameter. For example, if logs are 20 cm in diameter, pegs should be up to 80 cm long, ensuring each peg securely connects 3–4 logs simultaneously.

Recommended reading: Log cabin assembly – different techniques.

$ Log Cabin from Processed Round Timber – Price

Building a 100 m² log cabin from pre-processed, milled timber starts from $25,000. This price includes only the cost of logs, delivery, and assembly on an existing foundation.

Photo 11 – Luxury log cabin made from processed round timber

Costs for finishing works and utility connections are calculated individually per project. Turnkey cabin pricing starts from $50,000.

\" \"